The Real Cost of Automating a CNC Machine with a Robot

Posted on Nov 02, 2022 in Automation

5 min read time

Are you thinking of automating your CNC machine with a machine tending robot? You're almost certainly wondering how much it's going to cost you.

With some types of automation solutions, it can be hard to accurately estimate the cost of automating the machine. Various factors will affect how much of your budget the automation will need.

For years, the true cost of automation has been very tricky to clarify. This is largely because conventional automation solutions are usually custom-designed to fit the specific needs of a particular business and task.

These days, it's easier than ever before to get a clear figure on the cost of automating a task like CNC machine tending.

In this article, we'll look at some of the key considerations you need to make when trying to calculate the actual cost of automating a CNC machine with a robot.

What is the true cost of CNC automation?

When you purchase a robotic solution, the "sticker price" of a product rarely tells the complete story.

With automation, the robotic hardware is only a small part of the equation.

The real cost of an automation solution will include a variety of factors. These include both one-off, upfront costs — like the cost of installation and the cost of any additional extra technology required for your task — and ongoing costs, like maintenance, training, and support.

Not all types of robotic solution will experience these costs in the same way. For example, if you choose to go completely DIY with your robotic solution — without using an application kit to simplify the deployment — you won't have to pay for an external integrator. However, you may have to pay for training and you will certainly have to pay the wages of the team members who deploy the robot.

Factors that affect the cost of automating a CNC machine

What types of factors will affect the cost of automating a CNC machine with a robot?

Costs you might need to consider include:

-

The robotic hardware itself (e.g. robot arm, controller)

-

Any additional hardware needed for your specific task.

-

Robot programming software if not included in the solution.

-

Labor costs to install and deploy the automation solution, either in-house or outsourced.

-

Any lost productivity during the integration process.

-

Modifications to your CNC machine if the robotic solution can't be deployed in a non-intrusive way.

-

Training team members on how to operate the machine tending robot.

-

Support and maintenance costs for hardware and software.

-

Testing of the solution (in terms of time and sometimes other resources) before putting the robot to work.

You can see how the cost of robotic automation can mount up if you are not aware of all these factors.

But this doesn't mean that machine tending automation need be expensive. With the right solution, it can be very cost-effective.

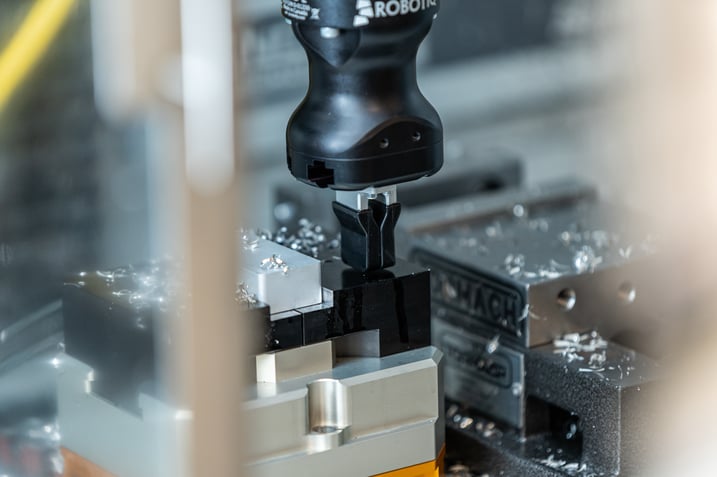

For example, using a robot application kit can remove a lot of the costs traditionally associated with robotics. With such solutions, it's much easier to get a clear overall cost.

The 3 types of robotic automation: Bespoke vs DIY vs off-the-shelf

You can think of there being 3 different types of robotic solution for CNC machine tending. Which type you choose will affect how easy it is to calculate the true cost of automation for you.

These 3 types of CNC machine tending solution are:

-

Bespoke — These solutions involve hiring a specialist robotic integrator to custom design and integrate a solution for your specific needs. Bespoke solutions tend to cost the most and are the hardest to get a clear price.

-

Do it yourself (DIY) — These solutions involve purchasing the required components and integrating them yourself. The cost of these solutions can vary hugely. While the upfront costs are usually lower, they require dedicating time and resources from your team members, which always has associated costs.

-

Off-the-shelf — A newer type of robotic solution, application kits involve purchasing a pre-designed, ready-to-use solution. They cost less than a bespoke solution and are much easier to use than a DIY approach, which reduces integration time significantly.

To determine the overall cost of machine tending, it's easier to get a clear cost with an off-the-shelf solution. There are far fewer "unknowns" than with bespoke or DIY automation.

How to find the real cost of a machine tending solution

Here's how to get a clear cost of machine tending automation using the 3 different types:

Bespoke machine tending solution

With bespoke solutions, the robot integrator will need to calculate the cost of automating your CNC machine for you.

Be aware that you will probably have to do a bit of extra "pushing" to get a true cost from them. The price that your integrator quotes upfront may only be for certain aspects of the deployment (such as core hardware components, deployment, etc).

Be proactive and ask them about the other factors that will affect cost over the lifetime of the automation solution.

DIY machine tending solution

With DIY machine tending, it's hard to get a clear idea of overall cost.

You can start by calculating the cost of the hardware and software components. Talk to one of our integration experts if you'd like to speed up this process.

Factors like the cost of integration time and training will also affect your cost differently, depending on how much robotics expertise you already have in your team.

Off-the-shelf machine tending application kit

With a robotic application kit, the overall cost is easier to determine. Just find a suitable application kit for your chosen task and ask for a quote.

When you contact your supplier, ask about any other costs that might be associated with using an off-the-shelf solution. There are fewer "moving parts" in such a deployment compared to the other options, so they should be able to give you a clearer figure.

Choose the right type of automation for your business

Each type of machine tending solution has its own benefits and drawbacks.

While it's easier to get a clear cost with an off-the-shelf application kit, there are good reasons you might choose a bespoke or DIY solution, particularly if your task requires high customization.

By considering all the factors involved in the cost of automating your CNC machine, you can make the best decision for your business needs.

What questions do you have about the cost of automating a CNC machine? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, or the DoF professional robotics community.

1_2026_Siemens_UR_demo_CES2026.gif)

Leave a comment