The one Robotiq product I cannot live without

Posted on Apr 16, 2021 in Collaborative Robots

2 min read time

As the owner of several Universal Robots UR series cobots, there is a wide selection of end effectors and accessories available to me. But there is one accessory that I will never again go without – The Force Copilot from Robotiq.

ActiveDrive toolbar

Any cobot programmer can identify with the struggles of holding down the pendant button while trying to manipulate the end effector into place with one hand. At times, I’ve called over a coworker simply to hold the pendant button down while I move the arm. More commonly, the planar alignment of the end effector to the workpiece is also lost. Sure, jogging the arm manually is an option, but it is a painfully slow and tedious process. The Force Copilot solves this problem.

After a simple 3-minute software installation, the Force Copilot was active and ready to use. Most people might be drawn to it because of the more notable nodes such as Path Recording, Insertion, and Force Control, but a toolbar known as Active Drive that appears in the corner of the screen is the hidden gem of the product. Allow me to explain.

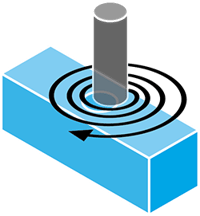

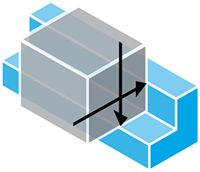

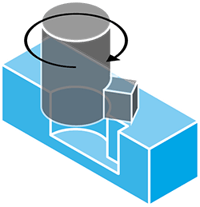

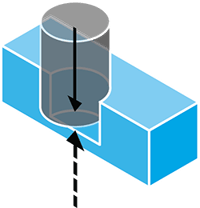

This toolbar allows you to move the arm with both hands without holding the pendant button. Did you catch that? You can use two hands without holding the pendant button! When active, several movements and constraints are presented. The first is Free Mode which is similar to the default behavior, just without needing to hold the pendant button. The next, and most useful in my opinion, is known as Scara which keeps the Z axis of the robot end perpendicular to the starting position. This is incredibly useful when programming the robot to move from a flat table to a camera position to a vise in a cnc mill. The Plane mode keeps the Z perpendicular as in the Scara mode but also keeps the X and Y perpendicular to their respective planes. No inadvertent rotating of the end effector is possible. This is useful for machine tending applications where keeping the workpiece square to a loading table or vise is important. The last pain point the Force Copilot relieves is when all other positioning attempts have failed. Simply tap the Reorient icon to perfectly align the tool vertically with the robot base.

Our cobots are there to work with us, not against us and these seemingly small quality-of-life enhancements make an incredible difference in positioning, programming and deploying a successful automated process without the micro frustrations. The Force Copilot is worth every dollar.

Leave a comment