What’s the real cost of palletizing automation?

Posted on Oct 14, 2025 in Collaborative Robots

6 min read time

When manufacturers think about automating end-of-line operations, one question almost always comes first: What does a palletizing solution really cost?

The short answer: it depends. The full answer: it’s not just a cost; it’s a strategic investment in efficiency, consistency, and scalability.

At Robotiq, we’ve redefined what automation means for the factory floor. Through The Lean Palletizing Experience, we help manufacturers move from manual to automated cobot palletizing with digital clarity, production-ready speed, and modular scalability.

The bigger picture behind automation costs

Automation costs aren’t only about hardware. They’re about time, complexity, and how quickly you start seeing results.

Manufacturers are often forced to choose between two extremes:

- Rigid pre-packaged systems that can’t adapt to changing needs.

- Custom-built projects that require heavy engineering and long timelines.

Neither option delivers the flexibility or predictability that modern production demands. That’s why Robotiq offers two clear paths within one unified experience: PAL Ready and PAL Series. But more on that later. Let’s take a closer look at overall costs and some considerations to take into account for custom solutions first.

Cobot System Costs: What’s Included?

When you’re budgeting for automation, it’s important to recognize that the cobot arm is only one part of the equation. To truly get value from the cobot, you’ll need additional elements, including:

- End-Effector: This is the part of the system that interacts with the product, such as a gripper or suction cup, and its cost varies depending on the specific task.

- Integration & Setup: Depending on your production line, you may need to modify existing systems (conveyors, air systems, electrical infrastructure) to accommodate the cobot.

- Software & Programming: A cobot might require custom programming to function in your specific environment, or, in some cases, you may need a specialized interface to help the cobot interact with your existing systems.

If you’re opting for a turnkey system where everything is pre-packaged and ready to go, the cost of a cobot system can be quite reasonable.

However, if your application requires a more customized solution, the cost can escalate quickly. In these cases, the cost of engineering expertise and the time required to create a tailored system can drive the total cost much higher.

Custom Solutions Considerations

One of the biggest factors that can increase the cost of a cobot system is custom engineering. If you have a complex task that requires specific tooling or specialized modifications to your production line, you’ll need to invest in engineers to design and implement the solution.

Engineering talent, particularly those experienced with automation systems, is in high demand and can come at a premium. Custom solutions also tend to have longer lead times, meaning you’ll need to plan ahead for the potential delays in getting your system up and running. Additionally, custom systems might face reliability challenges since they often incorporate unique components that have not been mass-produced or thoroughly tested over time.

That being said, a custom solution may be necessary for certain tasks, and in those cases, the increased investment could yield valuable improvements in efficiency and productivity.

However, if your task is relatively simple, an off-the-shelf system can do the job effectively while also keeping costs down.

PAL Ready, production-ready from day one

As mentioned earlier, manufacturers are often forced to choose between two extremes: rigid pre-packaged systems that can’t adapt to production changes and custom-built projects that require heavy engineering and long timelines.

PAL Ready and PAL Series offer a third option.

PAL Ready is a fully assembled and production-ready palletizing cell—ready to run on-site the moment it reaches your facility.

It’s built for manufacturers who want results immediately, without the headaches of design phases or programming delays.

Key features include:

- Smart Infeed – automatically delivers boxes at the right time and place.

- Mobility features – move between lines or clear floor space in minutes.

- Built-in safety scanners – ensure protection without bulky fencing.

- PowerPick Multi Vacuum Gripper – handles product changes with zero changeovers.

With PAL Ready, you can start palletizing on day one and reach ROI faster through predictable performance and minimal downtime.

PAL Series, modular palletizing that grows with you

For facilities that need more flexibility, PAL Series offers a modular approach built on Robotiq’s standard PE and AX Series models.

You can configure your system to match your application—whether it’s adding new SKUs, changing box dimensions, or expanding to multiple lines.

Every PAL Series cell shares the same:

- Operator interface and software.

- Digital tools for design and validation.

- Lean Robotics logic for consistent results across all sites.

That means when you grow, you don’t start over; you scale within the same reliable experience.

The Lean Palletizing Experience

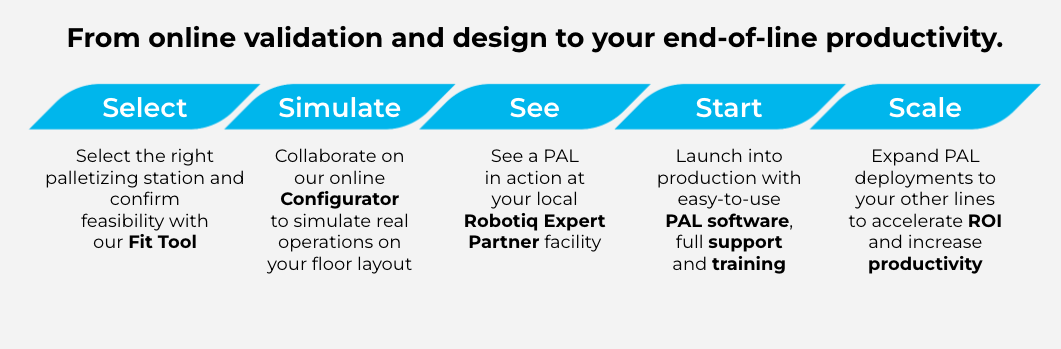

Both PAL Ready and PAL Series are part of The Lean Palletizing Experience—a structured, five-step journey that transforms automation from complex projects into a repeatable process.

- Select – Identify the right opportunity using the Palletizing Fit Tool.

- Simulate – Validate your layout online with a full 3D simulation.

- See – Visit a Robotiq Expert Partner to see PAL in action.

- Start – Launch into production with expert support and training.

- Scale – Expand to other lines or facilities for greater efficiency and ROI.

This digital-to-physical path turns uncertainty into clarity and helps manufacturers start fast and scale with confidence.

ROI you can measure — and the cost of waiting

Return on Investment (ROI) isn’t just about what you spend; it’s about how quickly you recover it.

PAL Ready customers typically see ROI in 1-2 years, thanks to reduced setup time, consistent uptime, and simplified maintenance.

But the cost of inaction is often higher: continued labor shortages, safety risks, and lost productivity. Waiting to automate means falling behind competitors who are already reaping the rewards of automation.

The Hidden Benefits of Cobot Automation

Beyond the obvious financial benefits, cobots also offer intangible advantages that can have a significant impact on your business. These include:

- Reduced Ergonomic Risks: Cobot palletizers can take on repetitive, physically demanding tasks, reducing the risk of injury for your workers and improving workplace safety.

- Employee Morale & Retention: By automating repetitive tasks, you allow your employees to focus on higher-value work, which can improve job satisfaction and morale.

- Flexibility and Scalability: Cobot systems are highly flexible and can easily be reprogrammed for new tasks or scaled to meet increased demand. This makes them ideal for businesses that need to adapt quickly to changing market conditions.

- Enhanced Customer Perception: Many businesses find that customers appreciate seeing automation in action, which signals innovation and a forward-thinking approach.

See your ROI before you buy

So, will Lean Palletizing be cost-effective for your factory? Before committing, know exactly what automation can deliver for your production line(s).

👉 Try the Robotiq Palletizing Fit Tool to receive:

- A custom 3D simulation of your palletizing cell.

- ROI and payback calculations based on your production data.

- A downloadable report you can share with your team.

Start fast. Scale with confidence.

Leave a comment