New Collaborative Robots at iRex 2015

Posted on Dec 04, 2015 in Collaborative Robots

5 min read time

We visited iREX 2015 this week at the Tokyo, Big Sight. It was great to be in robotland and to be immersed in Japan's point of view on robotics. Some known collaborative robot manufacturers are now very familiar with this show and use it to unveiled their new cobots to the general public for the first time. Here's what we have found/learned during the show.

Tokyo Big Sight Central Court

The big guys in the game

- Yaskawa HC10

A brand new robot from Motoman/Yaskawa. The robot seems to have the same principle as the Green Fanuc: an OEM industrial robot, covered with a rubber skin (blue this time) to eliminate pinch points and sharp edges. As I understand it, the difference between their concept and Fanuc's is that force is monitored in each joint compared to at the base of the robot for Fanuc. Yaskawa also showed its new YRC 1000 controller that is being used for this robot. The new robot is supposed to be released next year.

- Other Green Fanucs

Talking about Fanuc, they released a complete line of collaborative robots: CR-4iA, CR-7iA and CR-7iA/L, in addition to the existing CR-35iA. What I understand is that they are using the exact same principle, but scaled down a bit for the different models. So a soft cover, force-torque sensor at the base of the robot and the regular programming method. I guess they had a good response with their first model and wanted to re-use it. In any case, it is a good concept and does not require a totally new robot... so why not use it again. All robots are offered with vision and force torque sensing.

- ABB Roberta dressed in white

It has been a while since we saw Roberta. In fact, do you remember the purchase of Gomtec by ABB? This was the first time we saw Roberta with its new look. In fact, the robot is now part of the YuMi family. The team has been working on porting the robot into the ABB architecture. So I guess that software and mechanical devices had to be adapted to run like an ABB unit, while keeping all the interesting stuff that Gomtec had developed in the past. To be honest it looks quite good (especially in white). The hardware of the robot is flawless and the sensor at its wrist makes control nice and easy. I don't have any info on the official release date though. ABB was also showing the original 2 armed YuMi. - PS: No offence, but I am pretty stoked to see Roberta in a legit marketing campaign and not just as a flowery backdrop.

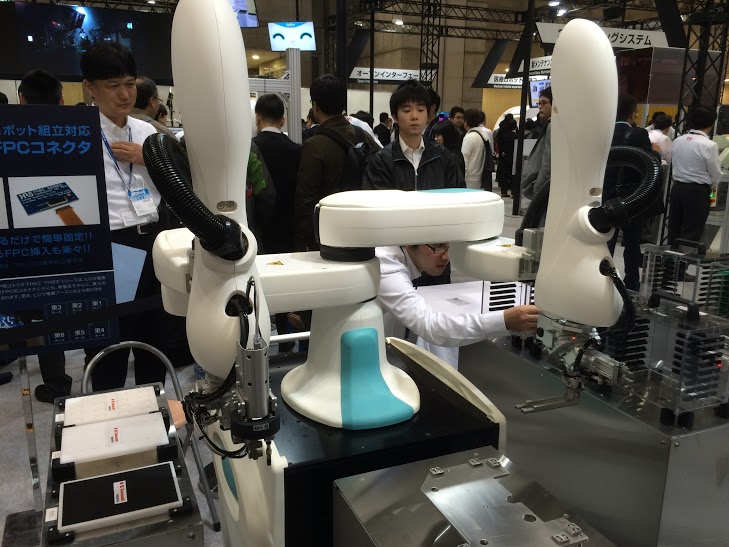

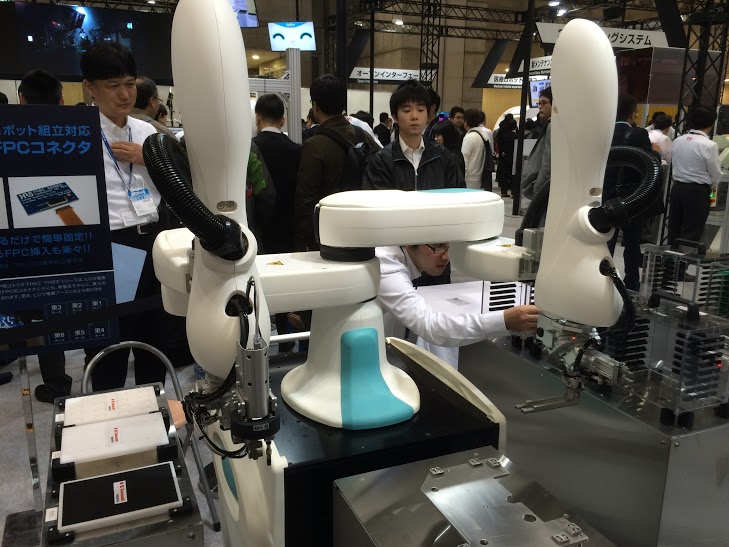

- Kawasaki duAro

Kawasaki presented its new addition, the dual arm scara robot: duAro. The robot is a great fit for electronic assembly where most motions are planar. The robot is designed to be collaborative. In electronic assembly lines where a lot of dexterity (human workers) is needed, it is just normal to have these devices being power and force limited. The robot was announced last summer.

New kids on the block

- Life Robotics CORO

This is a new Japanese company, which expects to begin selling robots next year. The robot seems to be innovtive by having one retractable segment to increase its reach. The robots will only be sold in Japan initially. Original use of prismatics makes this robot’s footprint very compact. They have been pretty secretive about pricing which makes me expect a really cheap price. - TM Robotics (subdivision of Quanta Storage, maker of the Apple mac book which I'm typing this article on)

A company that comes from the IT industry will certainly give you an easy to use, totally integrated solution. And this is what is happening here. The robot is smart, simple and safe; has integrated vision, integrated wifi and uses a tablet as its teach pendant. The Taiwanese robot is supposed to be released next year. This is going to be an interesting one to follow.

The usual suspects :

- Kawada had an impressive demonstration integrating several robots. The Nextage being their industrial robot, it seems to work well and have great capability, but as far as I know, it is only available in Japan. Kawada was also showing its HRP-2 and HRP-3.

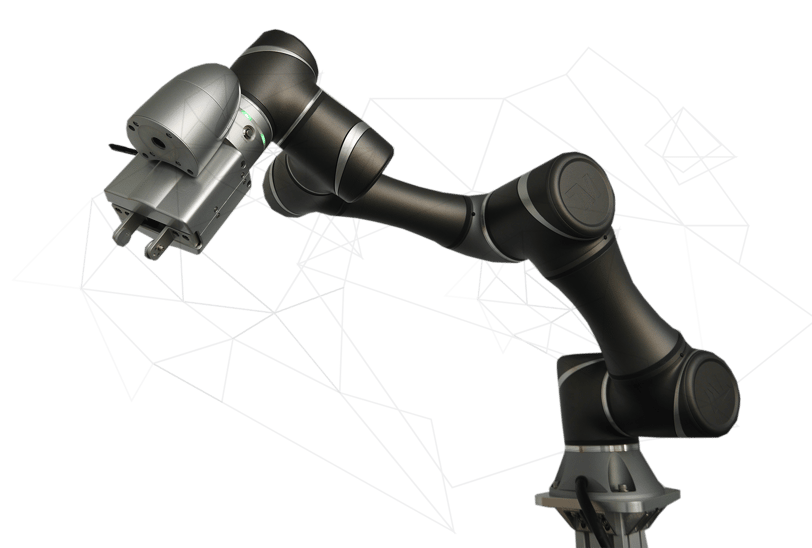

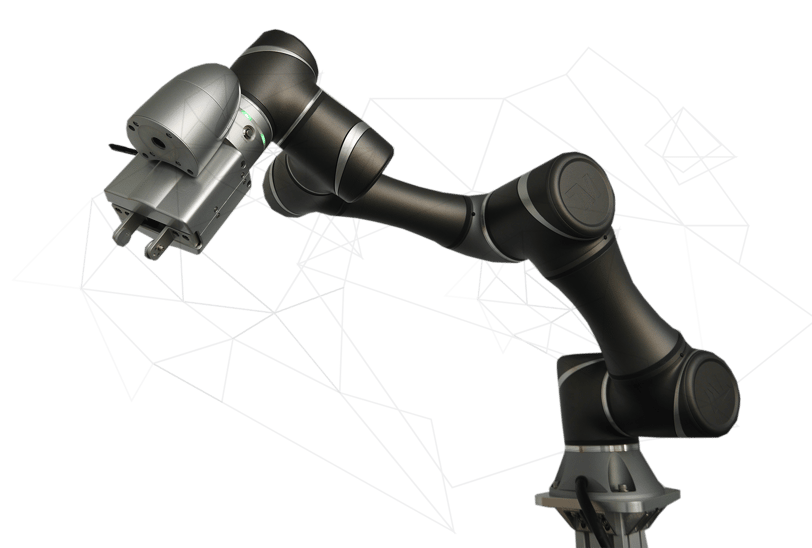

- Universal Robots was showing applications with some local partners using Robotiq Grippers. Notice that the UR product line remains untouched with the UR3, UR5 and UR10.

- Rethink Robotics was showing Sawyer with Simumoto, a local partner in Japan.

- KUKA was focusing completely on LBR iiwa in their booth, showing assembly tasks.

As you can see, the offerings for collaborative robots are increasing rapidly. All the big players in the industrial robots field are coming up with not just one, but entire product lines of collaborative robots. This has the potential to be a game changer for collaborative robotics, and move it from a niche, innovative market space into the mainstream for manufacturing companies

I wonder how the new ISO TS 15066 standard for collaborative robot safety will affect the growth and evolution of these new products? Will we all have to go back to the drawing board and adjust our product design, or have we built enough safety into collaborative robots already? One thing is sure though, with this show, our eBook on collaborative robots will need to be enhanced, you can still take a look at what can be bought right now. We promise to put out an updated version as soon as we have enough detail on each robot.

And lastly, how will these new product lines affect the market for end effectors: pneumatics are not seen often on collaborative robots - will this stimulate demand for electric end effectors? Other technologies?

What do you think?

Leave a comment