How to Palletize a Shipment Faster and More Efficiently

Posted on Jan 25, 2022 in Palletizing

5 min read time

Like all manufacturers, you have products to ship and a limited time to ship them in. How do you palletize a shipment faster without compromising quality?

Palletizing can be a real bottleneck for companies. Often, there's no dedicated person for the task. Workers have to rush to fit in a bit of palletizing whenever they get a spare moment. Shipments are left unpalletized for far longer than you would like.

Even if you do have a dedicated palletizing worker, the task is physically demanding and highly repetitive. Over the course of a long shift, the quality of the palletizing can drop, leading to product slippage and damaged items.

You want to get your shipments out the door faster, but the palletizing step is delaying the whole process.

Do you make this mistake when you palletize a shipment?

What causes slow palletization?

With manual palletizing, various factors contribute to the speed at which you can get shipments out the door.

Seemingly simple factors like the operator position and pallet orientation can affect the task performance and the resulting packaging quality. Get these factors wrong and you will not only find that your shipments are taking a long time to palletize, but you may also find workers taking more sick days due to damaged backs.

Companies often try to overcome these challenges by introducing better ergonomics into the task of palletizing. They might purchase pallet lift tables so that workers can raise the pallets to a more ergonomic height.

Ergonomic workstations are certainly important for manual palletizing. But, they are often neglecting a key question…

Why use manual palletizing at all?

Yes, introducing extra equipment to improve palletizing ergonomics increases the safety of the task. But, the equipment itself can reduce the speed of palletizing even further. Workers need to spend extra time operating the lift tables, which means less time palletizing.

Wouldn't it be easier if you weren't relying on the worker for palletizing at all?

The real bottleneck: the palletizing worker

Palletizing is a dull, repetitive task. This is not the type of work that humans excel at. Humans are much better suited to tasks that require skill, decision-making, and cognition.

When you think about it, it's clear that we humans are the bottleneck for palletizing tasks.

Palletizing a shipment efficiently relies on several factors including:

- Consistency — Inconsistent palletizing leads to sloppy shipments. In turn, this causes damaged or lost items during shipping. Even the best palletizing worker in the world will start to introduce some inconsistencies during a long shift.

- Regularity — It's much easier to prepare shipments efficiently when palletizing happens at a strict regular cadence. In many facilities, human workers palletize in short bursts when they have a spare minute from their other tasks. This can lead to product piling up and makes it hard to optimize the process.

- Speed — Humans can certainly palletize products quickly when needed… but we don't move at a consistent speed. Ideally, you want your palletizing process to maintain a consistent speed over the entire work shift.

- Accuracy — Accurate box placement is vital if you want to ensure the contents of your pallets don't shift during shipment. We humans can place things fairly accurately when we are paying close attention to our movements, but over long work shifts, our accuracy suffers hugely.

Clearly, humans are not ideal for a task like palletizing.

Thankfully, there is a far better way to ship your products faster…

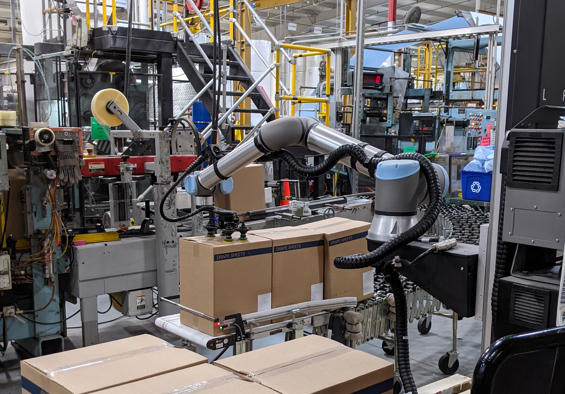

How a palletizing cobot can make your shipments more efficient

Robots have been used for palletizing for many years. Large manufacturing companies that ship very high volumes have long used palletizing robots to quickly prepare their products for shipment.

In such large companies, the products are highly consistent so the robot performs exactly the same motions for days on end. Efficiency is central to such operations — even a saving of a few seconds per pallet can mount up to huge efficiency gains due to the large number of shipments.

However, for smaller companies or those with a high mix of products, robotic palletizing is still relatively new.

Recently, collaborative robot palletizing has introduced a way for almost anyone to access the benefits of robotic palletizing.

What makes cobots such an effective method to improve shipment efficiency?

You just need to compare the core strengths of collaborative robots with the list above to see why they are so much better suited to palletizing than human workers:

- Cobots are highly consistent — The major benefit of robots is that they are consistent. They will perform the same task in exactly the same way every time. This is extremely useful for palletizing as it ensures boxes are always placed in the right place. They also have a highly consistent speed.

- Cobots are accurate — Unlike humans, cobots don't get sloppy with their box placement when it's coming up to lunchtime. If a box needs to be placed at 90° to the previous layer, it will always be placed at exactly 90°.

- Cobots are very easy to program — A general benefit of using collaborative robots over other types of robot is the ease of programming. This means that almost anyone in your facility can program them, including the workers who usually perform the palletizing. It also makes them very flexible to regular changes in product lines.

A palletizing cobot can become a key tool for improving the efficiency of your palletizing task, helping you to get your shipments out the door much faster.

Your first step for speeding up palletized shipments with a robot

How can you get started with collaborative robot palletizing?

A good first step is to have a look at what a cobot palletizer can do. You can see some example videos on our products page to get started.

What palletizing tasks do you currently have that are inefficient? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, or the DoF professional robotics community.

-2.png)

-1.jpg)

Leave a comment