Your Ultimate Guide to Efficient Pallet Stacking Patterns

Posted on May 17, 2022 in Palletizing

8 min read time

If you're using a cobot to palletize products, you'll want to ensure you're using the right palletizing pattern!

A good palletizing pattern helps you package your products securely, helping to reduce damage and returns.

In this article, we'll discuss 7 great patterns for cobot palletizing. We'll also look at some factors that go into making a good or bad pallet pattern, and how to select the best one for your task.

How palletizing pattern reduces damage and returns

Many factors can contribute to damage and returns of your products, but a factor people often overlook is the palletizing pattern. The right palletizing pattern can help to disperse weight in your shipment, minimizing friction and protecting your vulnerable products from impact.

It's important to consider the stability of the stack. An unstable stack is more likely to topple over, cause damage to your products, and even compromise the entire shipment.

There are several palletizing patterns you can use. The best one will depend on the products you're packaging, the size and weight of the products, and a few other factors.

Palletizing pattern calculators: Useful or not useful?

You can find several palletizing pattern calculators online.

These calculators can be helpful tools, but it's important to remember that they are only a starting point. This calculator from OnPallet, for example, allows you to enter your pallet and box data. I will then tell you what a single layer can look like with how many items will fit on it.

Beyond simple calculators, the Stackbuilder software is the "Rolls Royce" of palletizing programs. It's complex, but has all the functions you'll ever need to create any palletizing pattern imaginable.

Such software tools can be handy. But the best way to find the perfect palletizing pattern for your products is to test various patterns and see what works best…

A simple palletizing calculator usually isn't enough.

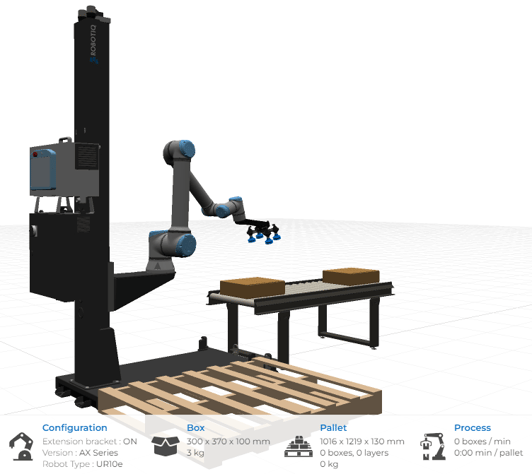

When you automate your palletizing, you'll want to ensure that your pallet size and type work with your palletizing solution. The Robotiq configurator is a tool that you can use to test this out with a collaborative robot.

What makes for a good or bad pallet pattern?

There are several factors to consider when choosing a pallet pattern, including:

✅ The weight of the load.

✅ The size and weight of each box.

✅ How stable you need the load to be. A good pallet pattern will distribute weight evenly and minimize friction.

✅ Whether you need extra space around the boxes.

✅ Whether you need to the boxes to be placed in different locations so you can read the labels or barcodes.

3 Tips for a good palletizing pattern

Here are three pointers for creating a stable pallet pattern:

✅ Minimize costs and waste by maximizing interlocking carton usage and pallet utilization.

✅ Set your pallet pattern for the type of pallets you'll be using.

✅ To improve stability, rotate each alternate layer.

First, you'll want to think about the weight and dimensions of your products. You'll also want to consider the fragility of your products and how vibration and impact will affect them.

Next, you'll want to think about the stability of the stack. Will the arrangement of the boxes provide any stability? Or will the main stability come from extra elements (such as shrinkwrap)?

Finally, you'll want to consider the ease of palletizing and depalletizing. A good pallet pattern should be easy to follow, and it should be easy for a robot to remove products from the pallet without damaging them.

7 great palletizing patterns for your cobot

Now you're familiar with some important factors when choosing a pallet pattern, here are 7 great palletizing patterns for your cobot:

1. The interlocked pattern

When stacking containers in a vertical arrangement, one difficulty is preserving the loads during transportation. As a result, many people use an interlocking pattern which "locks" the containers in place by staggering their positions.

This pattern is perfect for products that you need to stack securely. It is often used for heavier loads.

2. The partially interlocked pattern

In the partially interlocked pattern, some boxes overlap, but not all. It's composed of a base layer plus an interlocked top layer that's joined by columns.

When compared to a totally interlocked structure, this improves the strength of each vertically aligned layer by up to 45%.

Partially interlocked patterns are best for lighter loads and products that don't require as much stability.

3. The block or split block pattern

The Block Pattern is a type of column arrangement. Your palletizer will place each box on top of the one below it in the same sequence. This method works for certain items, but lack of interlocking may cause them to fall. It all depends on what you're palletizing.

A variation of this pattern is the split block, which involves dividing the pallet into two sections. The first section is a central column of boxes that hold all containers together. Around this column is the second section, where the boxes are stacked on top of each other, as with the block pattern.

This is useful for products of different sizes because it prevents them from toppling over.

4. The brick pattern

With The Brick Pattern, you don't stack the cartons in the same way as you would with a column arrangement. Rather, you stack them one on top of another, alternating between layers, like a brick wall.

One disadvantage of this approach is that it unevenly distributes the weight at the weakest point of each carton. We don't recommend using this method for heavy loads because it puts too much stress on the bottom layer.

5. The row or split row pattern

This is like The Brick Pattern, but we turn each layer 90 degrees compared to the one below it. It provides extra interlocking for stability, but it's not as complicated as The Pinwheel Pattern (see below).

The Split Row is a variation of this pattern which provides some extra stability. With a split row, you have a standard row design, but you place one box in a different orientation in each row to lock the rest in place.

This is useful for products of different sizes because it prevents them from toppling over.

6. The pinwheel pattern

A pinwheel is an interlocking pattern with some gaps, forming the boxes in the shape of a wheel.

You can use this type of pattern when the product has a tendency to shift during transportation. The gaps between the boxes allow for some movement, which can be beneficial depending on what you're palletizing.

It's also useful for products of different sizes because it prevents them from toppling over.

7. The column stacked pattern

Column stacking increases box stability by 25-30%. It evenly disperses the weight over each box's strongest point.

One problem with this approach is that it relies on ties or shrinkwrap for stability – the structure itself doesn't provide any stability. They are the only thing keeping boxes from tumbling in transit since all boxes are directly on top of each other.

How to select the best pallet pattern for your task

The path to success with palletizing is to plan. Experiment with various pallet layouts and see how they perform in our Robotiq Configurator.

If you have heavy boxes, you'll want to use a pattern that offers extra support, like the interlocked or pinwheel patterns. If you have lighter boxes, you can get away with a less supportive structure.

The size of the boxes is also important. If you're palletizing large boxes, you'll need a pattern that can accommodate them without sacrificing stability.

Finally, consider the contents of the boxes. If you're palletizing fragile items, you'll want to minimize movement to prevent damage. Here, for example, a pinwheel pattern might not be the best choice.

Don't believe that you can simply set up your palletizing task once and leave it. You may need to alter your pallet designs over time, allowing for continuous improvement.

Robotiq Palletizing Configurator: Design your robot pallet

With the Robotiq Palletizing Configurator, you can design your robot palletizing cell in minutes.

You just provide some basic information about your pallet and boxes. The Configurator allows you to create two layer patterns and switch between them in each layer. This approach provides the advantages of interlocking quickly and easily.

Now that you know more about pallet patterns, it's time to choose the best one for your needs!

What questions do you have about palletizing? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, or the DoF professional robotics community.

-2.png)

-1.jpg)

Leave a comment