Top 4 Reasons to Use an Adaptive Electric Gripper

Posted on Sep 26, 2014 in Robot Grippers

3 min read time

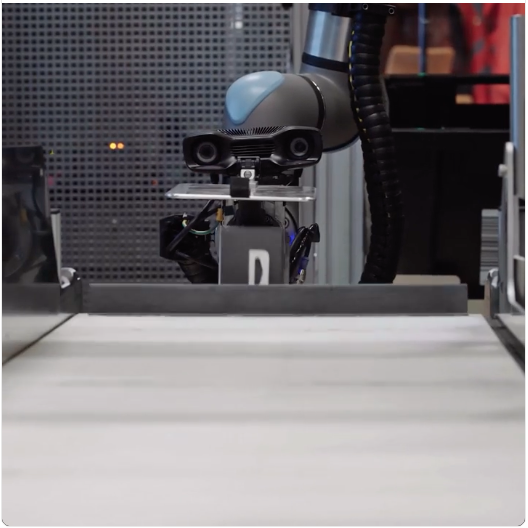

At Robotiq we are creating flexible robotic tools that can adapt to different processes on the fly. For this reason, we are constantly developing Adaptive Grippers that can be used for a whole lot of applications. The main advantages of an Adaptive Gripper are listed in the article below. Hopefully, this will help you find a gripper that will suit your application.

Flexibility

The main reason why our Gripper is called ''adaptive'' is because it can adapt to a very large array of situations. In fact, since the Gripper is underactuated, the fingers can adapt to different shapes and still have a strong grasping effect on them. These end-effectors are installed in workshops that require processing for a wide and varied mix of parts. The application might be for pick and place of a lot of different parts or just because the part production has a ton of different diameters and nobody wants to have to stock a ton of different grippers.

Long Programmable Stroke

Once again in comparing with other grippers out there, the Adaptive Gripper has a long stroke for its size. Since the gripping length is long, you have the opportunity to program it as you wish. The Grippers all have different strokes, but they can be controlled with a 0 to 255 bit range. So you have a wide choice of configurations. For example, if you want your Gripper to grasp a small object you don't have to open the Gripper to its full length and then close it again. In fact, you have the choice of opening the Gripper as small as you need to fit your application. This means that you aren't waisting time opening and closing the Gripper unnecessarily, which will save production time in your overall application process.

Robust Design

Our Gripper designs are tested in-house to assure long term reliability for our customers. We also have a lot of Grippers in workshops and research centers that are working in different environments. From welding shops to assembly lines, our designs have been field tested and proven. We are pleased to be able to report that the feedback from our customers is that they continue to work well.

Easy and Fast Gripper Integration

Integration is easy because all the Adaptive Grippers are designed to fit most of the robots available on the market today. Though there is no standardization in robot manufacturing certain physical attributes are common and we are constantly increasing our robot compatibility. In fact, to help with compatibility we have a list of the different robots that match up with our different Grippers. You can find this list at the very end of our product list.

The communication and power requirements are also very easy to figure out. You basically have to order one or two communication cables depending on the Gripper model and you are all set. Take a look at the ''how to order'' section of our product list to figure out what set up suits your robot best. Robotiq also provides application programming interface (API) software to fit most of our Robotiq brands. The software allows you to configure your Gripper, but also to eventually program different routines with your Gripper.

.jpg)

Leave a comment