Robot Accuracy and Repeatability in Off-line Programming

Posted on Sep 09, 2014 in Robot Programming

2 min read time

This is a short introduction to the importance of robot positioning accuracy, which includes position and orientation accuracy. Note that by robot accuracy: we refer to the static accuracy of the robot or the accuracy of the robot without including the movements related to the end-effector.

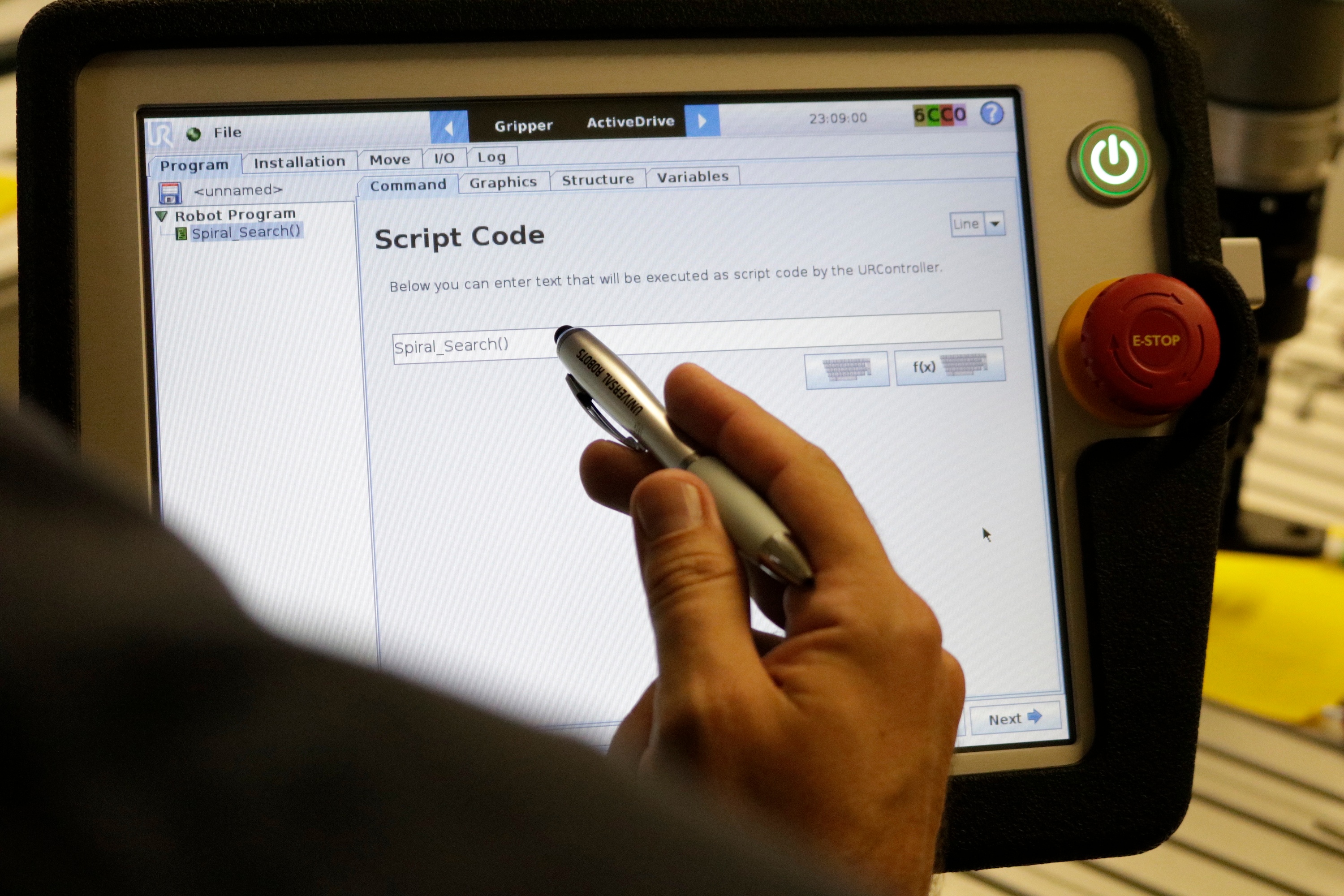

Programming an industrial robot is carried out by using two approaches either an on-line programming method or an off-line programming method. In the first method (i.e. the on-line programming or teaching approach) the robot’s end-effector is moved to several locations inside the robot’s workspace, and the corresponding pose (i.e. the end-effector’s position and orientation) are saved in the robot’s controller. The saved poses might be components of the trajectory or a set or sub-set of the main target poses. Such techniques are largely used with collaborative robots.

The on-line programming is a simple method and doesn’t require a lot of robotic programming knowledge, but it is a time consuming approach and during the programming process the robot is not used for production activities. Also, this method requires a good pose repeatability on the part of the robot, which mainly represents the ability of the robot to precisely reproduce the same desired poses, repeated many times. Note that, in the on-line programming, the desired poses are those saved during the teaching process. This is where having a force torque sensor to help with the input of data related to the positioning of the end-effector can really save a lot of time and effort.

To overcome the deficiencies of on-line programming (i.e. the time consuming/out of production aspects), another method is used in industry, where the robot is not physically used for programming purposes: The off-line programming method.

This approach is based on designing the robot's movement by using dedicated programming and simulation software, such as RobotGuide (Fanuc Robotics), RobotStudio (ABB Robotics) and Robot Master. However, this method requires fairly precise robot pose accuracy, to guaranty that the robot will accurately reproduce the off-line movements programmed and tested during the simulation (i.e. the off-line) process.

Usually, industrial robots have very good pose repeatability, but their pose accuracy is not quite as precise as their repeatability. Therefore, to make the best use of their off-line programming abilities, improving the robot's accuracy becomes a must. A standard method (ISO9283) dedicated to the evaluation of the robot accuracy has been proposed by the ISO (International Organization for Standardization).This is a good idea since it means that all the players in the robotics field can be using the same measurement standards for pose accuracy which will make it easier for end users to evaluate industrial robot arms.

Leave a comment