Why Did MIT Choose the 3-Finger Robot Gripper from Robotiq?

Posted on Feb 02, 2015 in Robot Grippers

3 min read time

Robotiq: Where did you first learn or hear about Robotiq Grippers?

Claudia Pérez D'Arpino: Our first experience with Robotiq Grippers was in the DARPA Robotics Challenge manipulation tasks. We also use the Robotiq 3-Finger Adaptive Gripper for manipulation in our dual arm dexterous manipulator.

Robotiq: I guess you did some testing with other brands or other types of solutions, why did you choose our Grippers for your final selection?

Claudia: The Robotiq Gripper proved to be reliable and durable, keeping the hardware in working condition despite frequent use in tasks that are demanding to both the material and the mechanical parts.

Robotiq: Was there a key feature that convinced you to choose the 3-Finger Adaptive Gripper?

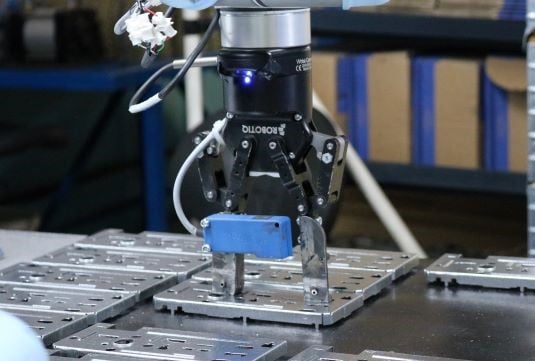

Claudia: The shape and size of the palm and fingers together with rotations of the fingers make the hand very usable in practice, whereas the ability to apply force even with the tip of the fingers through the under actuated mechanism is key in enabling manipulation of objects in constrained spaces.

Robotiq: Are there any other Robotiq devices that would be interesting for your research?

Claudia: We are interested in exploiting the capability of force/torque sensors, both on the wrist and the surface of the palm and fingers (tactile sensors), in order to evaluate the quality of a grasp.

We are flatter that the MIT team have choose our products to acheive their tasks during the contest. Robotiq Grippers are used in important projects, such as the DARPA challenge by several different teams and apear to be appreciated by their users. We appreciate that different research labs are finding innovative ways to use our Adaptive Grippers. This expands what they are capable of doing and allows us to see what applications work well. To have more info on the uses of the 3-Finger Adaptive Gripper in research, we have put together an interesting document that highlights some of the more impressive projects we have come across. If you have found a unique use for one of our Grippers, please tell us about it. We are curious!

Leave a comment