The Lean Palletizing Experience: How to automate end-of-line palletizing with confidence

-modified.png)

For many manufacturers, the end-of-line is a pain point they can’t ignore. It’s where finished goods are stacked, wrapped, and shipped — but it’s also one of the most manual, repetitive, and physically demanding steps on the factory floor.

Today, many plants are feeling the squeeze:

- Labor shortages make it hard to find enough operators.

- Health and safety risks are on the rise.

- Costs keep climbing, threatening profitability.

You know automation could help... but you also know that traditional automation often comes with long timelines, expensive integration projects, and rigid systems that are hard to scale. So automation ends up feeling like a gamble, especially for a first project. At Robotiq, we're changing that.

A simpler way to automate

Robotiq created the Lean Palletizing Experience — a structured, repeatable approach that takes the guesswork out of automation. Instead of trading one problem (labor challenges) for another (technical headaches), you get a solution that “just works.”

Here’s how it’s different:

- Digital-first validation – You know how it’s going to work before you order anything.

- Production-ready hardware – Your palletizer is assembled, tested, and running on day one.

- Scalable architecture – Add new cells or new sites without starting over.

- Unified operator experience – Your team only needs to learn one system that works across multiple lines.

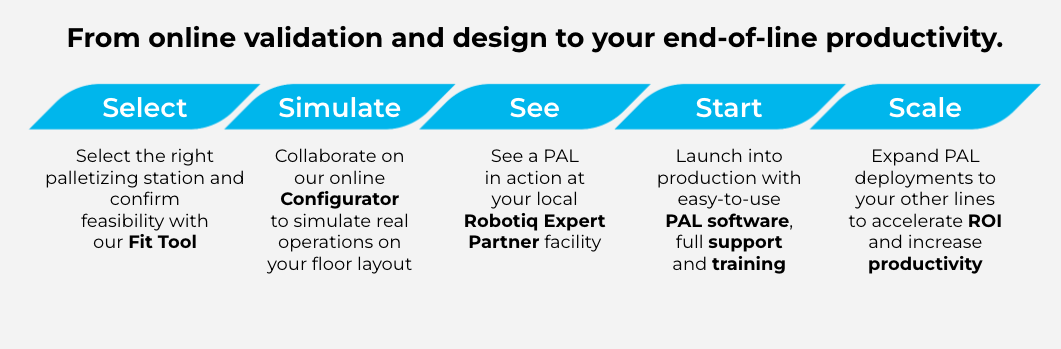

The five steps to confidence

The Lean Palletizing Experience is designed to build trust at every stage:

- Select: Use the Palletizing Fit Tool to check if your application is a good match and receive a tailored report.

- Simulate: Collaborate with our experts to design your layout virtually with the Online Configurator to see how it fits your floor.

- See: Visit a demo unit through our global partner network to see it live.

- Start: Launch your first cell quickly with PAL Ready (production-ready) or PAL Series (modular).

- Scale: Expand across lines and sites with the same software, tools, and training.

Busting the myths about automation

Still hesitant? Here’s what you should know:

- Too costly? Most customers see payback in 1–2 years thanks to labor savings and higher throughput.

- Only for mass production? Our solutions allow quick changeovers and adapt to batch runs.

- Takes too much space? Robotiq palletizers can run in as little as ½ a pallet footprint.

- Steals jobs? Automation takes over the dull, dirty, and dangerous work so your team can focus on higher-value tasks.

Ready to see for yourself?

Your first step is simple: try the Palletizing Fit Tool.

In just a few clicks, you’ll get:

- A custom 3D simulation of your palletizing cell

- ROI and payback period based on your real data

- A shareable report for internal decision-making

Start fast. Scale with confidence. Embark on your automation journey.

Fill out the Palletizing Fit Tool today and see if Lean Palletizing is right for your operation.

-2.png)

-1.jpg)

Leave a comment