New Robotic Vision Capabilities Break Down Barriers to Automation

Picking an object from a bin or unstructured pile has been an ongoing obstacle and deal-breaker for automation solutions. Amazon is so serious about finding an answer that Amazon Robotics organizes the Amazon Picking Challenge, now the Amazon Robotics Challenge, to help find solutions to automation problems: “Commercially viable automated picking in unstructured environments still remains a difficult challenge.”

To facilitate automation, trays are one way to ensure that parts are always presented with consistent structure, making them easy for robots without vision to pick. However, for some applications, trays are not a good solution since the parts change, making custom trays a cost-prohibitive solution. These picking issues have traditionally been a stopping point when evaluating the potential for picking automation.

Fortunately, advances in vision systems are now making automation, including collaborative robotic solutions, flexible enough for challenging picking applications. The eBook Vision Systems for Collaborative Robots from Robotiq offers a vision solution for automating the picking process for different parts: “Vision is a good option if you are often switching parts. You can usually teach a robot new parts to pick quite fast and there are no additional hardware costs when you use a vision system as opposed to jigs. Usually, you simply need to adjust the vision algorithm and you are good to go.”

Fortunately, advances in vision systems are now making automation, including collaborative robotic solutions, flexible enough for challenging picking applications. The eBook Vision Systems for Collaborative Robots from Robotiq offers a vision solution for automating the picking process for different parts: “Vision is a good option if you are often switching parts. You can usually teach a robot new parts to pick quite fast and there are no additional hardware costs when you use a vision system as opposed to jigs. Usually, you simply need to adjust the vision algorithm and you are good to go.”

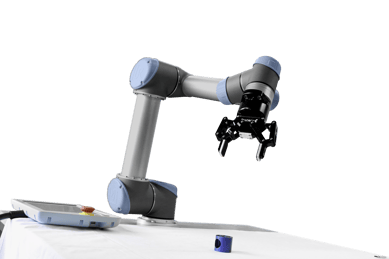

If a previous analysis of automation potential showed an ROI problem due to custom tooling required for picking applications, it’s time to re-evaluate. Vision-guided robotics are quickly moving beyond investment-intensive complex, customized solutions to widely available standard automation options. Released in 2016, the Robotiq Camera Plug+Play Vision System provides an easy-to-use vision solution that fits the wrist of all Universal Robots. Watch this video to see how the wrist camera allows the Gripper to pick up parts in a disorganized pattern.

Implementing the right robotic solution can be extremely cost-effective. The Robotics Industries Association lists Better Process Improvement in the article How Robots Cut Costs: “Equipped with machine vision technologies and wireless Internet, they [robots] can capture data other devices, and even human observers, can’t.”

Quality Assurance is another excellent opportunity to achieve impressive automation results with vision systems. Whether the issue is fill levels, label validation, or identification, vision systems are now performing at remarkable levels. Examples of automated vision systems performing well are turning up in all kinds of manufacturing processes. The Latest Robots Lend a Helping Arm at Factories article from the Wall Street Journal explains how a Universal Robot is taking photographs to look for defects in a dryer manufacturing operation. The Automated Inspection System article featured in the October issue of Vision Systems Design highlights a vision system that uses thermal imaging to verify proper glue application.

To learn more about vision system capabilities and participate in discussions about application possibilities, visit the Robotiq DoF community. This community-based discussion group of automation professionals is collaborating to advance robotics projects, including new vision systems.

Leave a comment