Choosing the Right Robot Gripper for Your Environment

Posted on Oct 03, 2014 in Robot Grippers

3 min read time

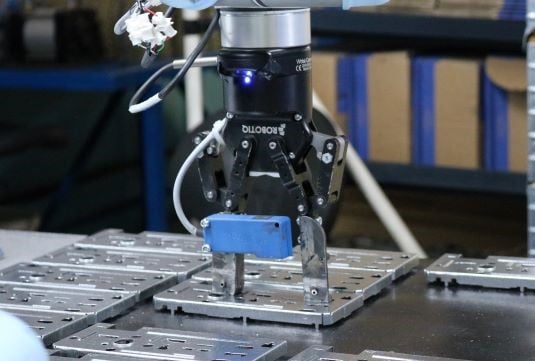

In the last blog post we discussed the best way to choose a gripper depending on he kind of parts you need to deal with. We also introduced what you should look at, depending on your assembly or machining processes and your part feeding processes. We also considered that the environment where the gripper is working should play a big part in the choice of gripper. Here we have detailed a couple more points concerning environments that you should look at before buying a gripper.

Temperature

Most of the time when the temperature is a limiting factor in your application, it's more often too hot than too cold. If the gripper is working near a welding torch or hot casting equipment the requirements are different than if it's working in a temperate environment. In general the gripper manufacturer will provide an optimal temperature range for operations. This range should be respected due to different factors. In fact, some gripper components can develop serious damage if the gripper is operated outside of its operating range.

Even while we speak of temperature, explosive environments should also be considered when making the choice of a gripper. Some plants out there are working with powders or gases that can explode when they come in contact with an electric motor or spark. This is a very limiting factor in your choice of gripper, because it's not just about the functionality of the gripper, but about the security of the plant. I know that some available electrical motors are compatible with explosive environments, if this is your case then you will have to look carefully at what the different options are for your robot and gripper application.

Fluids

Some applications such as machine tending use a lot of fluids. Coolant, water and other liquids can damage your gripper if it doesn't have the required protection. If you have applications with a lot of fluids involved you should make sure that the mechanism and electronics (if applicable) are well protected. You should also monitor the quantity of fluids that the gripper will come into contact with. In fact, if there is a lot of fluid in the application, but your gripper is not touching any of it, you could perhaps consider a lower protection than if the gripper has to be submerged in liquid.

Some applications such as machine tending use a lot of fluids. Coolant, water and other liquids can damage your gripper if it doesn't have the required protection. If you have applications with a lot of fluids involved you should make sure that the mechanism and electronics (if applicable) are well protected. You should also monitor the quantity of fluids that the gripper will come into contact with. In fact, if there is a lot of fluid in the application, but your gripper is not touching any of it, you could perhaps consider a lower protection than if the gripper has to be submerged in liquid.

To know what type of protection you need, the IP Rating is a good way to quantify it. In fact, the different ratings will help you monitor your application and determine your needs. All Robotiq Grippers are rated IP 67 which means that they are ''dust-tight'' and that they are protected against water penetration from 1 to 30 minutes.

Cleanliness

Are there going to be some metal shavings or dust on the gripper? Does your process use small parts that can enter into the gripper mechanism? These are all questions you should ask yourself when you are looking for a gripper. You should notice that the IP Rating is also available for solid state intrusion. Make sure to choose a gripper that will have the required rating for both dust and fluids.

Also, if the process needs to be done in a dirty environment, a cleaning station would be a great option to have available so that you can periodically clean your gripper. You should note that a clean gripper is not all about functionality, but also about accuracy. In fact, if your gripper's pads are dirty, less accuracy is bound to be achieved when a part is grasped.

Ask...

You should definitively ask your gripper representative or application engineer if your applications are suited for certain types of grippers.

I hope this article presented some helpful ideas about what to consider when choosing a gripper for your specific environment. Please feel free to leave comments on our articles, it is always useful to read what you think about our blog posts.

Leave a comment