How To Attach An End-Effector To Your Robot

Since there are little to no established standards for attachment interfaces in the robot industry, many things are to be considered by end-effector manufacturers, integrators and users for end-effector attachment design. This post first explains how to determine the forces and moments that your end-effector attachment must hold. Then, we present ways of attaching the end-effector to the robot. An Excel spreadsheet can also be downloaded to get you started in your calculations.

How to design the interface

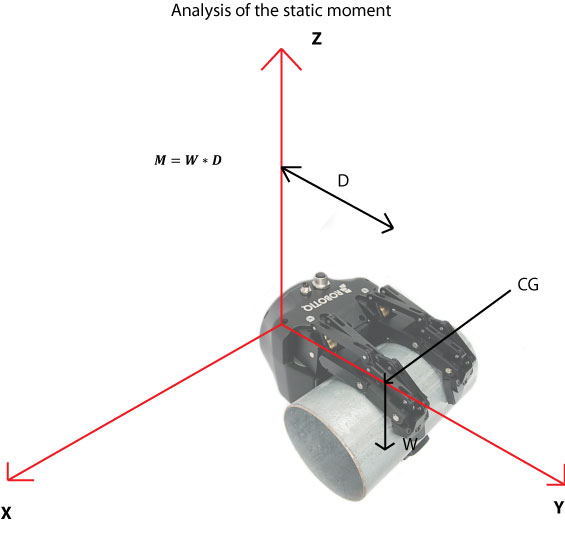

Basic method: the static moment.

- Find the center of gravity of the end-effector and the part: CG

- Calculate the distance from the CG to the bottom of the tool plate: D

- Determine the maximum weight of the EOAT and the part: W

- Calculate the static moment

- Select your interface so it can hold the the maximum static moment - note that the interface height adds to the distance D and increases the moment M

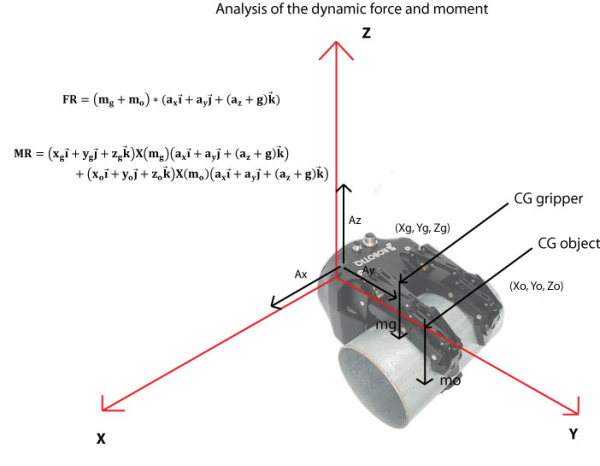

Advanced method: dynamic forces and moment analysis.

- Determine the CG of the object and of the gripper

- Determine the maximum weight of objects that will be grasped and of the gripper

- Determine the maximum acceleration occurring during the process

- Calculate the resultant force

- Calculate the resultant moment

- Select your interface so it can hold the the maximum static moment - note that the interface height adds to the distance D and increases the moment M

How to attach the interface

Now that you know the maximum payload and moment you can handle, you have to attach your end-effector to the robot. Keep in mind the height of the interface stacks to the centroid distance D. Increasing D does increase the resulting moment.

Using a faceplate: Related to the robot model, you will have various screw and dowel pin patterns.

- Screw the faceplate on the robot

- Insert the gripper, dowel pins provide orientation, precision and repeatability (each time you remove the gripper for tool changing or maintenance, the dowel pin ensures repeatability)

- Secure the gripper with the screws matching the interface, using Loctite will help

The above methods can also be used to determine the required specification for a robotic tool changer. On this topic, you can read the top 5 problems of robotic tool changers.

Leave a comment