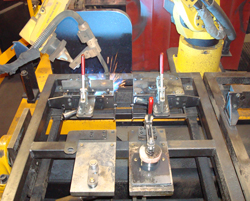

How to Achieve Good Part-Fit for Robotic Welding

Robotic welding is most useful when parts can be positioned in the same place, and with the same fit, every time a part feeder...

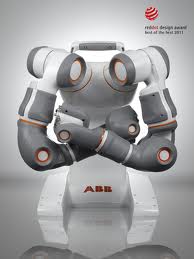

Collaborative Robot Series : FRIDA from ABB

In industrial automation, flexibility and intuitiveness are becoming more and more the sinew of war. In fact due to the...

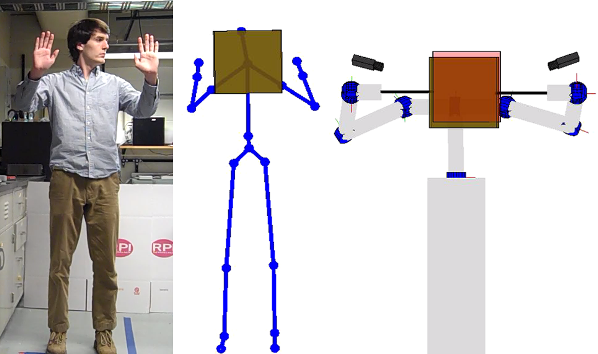

Two-arm teleoperation robot with Kinect and electric grippers

Maybe some of you have seen the following video from the guys at Rensselaer Polytechnic Institute (RPI) where a robot...

What You Need to Know About Robot Grippers

End-of-arm tooling (EOAT) decisions literally can make or break any robotic production process because the choices made affect...

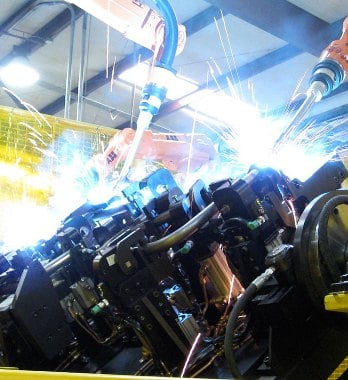

Top 5 Advantages of Robotic Welding

Robotic welding is becoming increasingly attractive for job shops and contract manufacturers because experienced welders can...

Top 5 Challenges of Robotic Welding Programming

Until now, robotic welding has been restricted to high production applications because of the length of time it takes to...

Leave a comment