5 Months? Too Long! How to Get a Robot Running in 3 Days

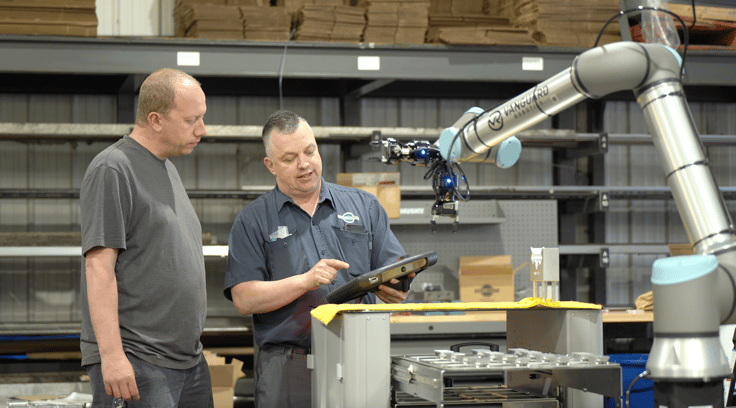

Deploying a robot can seem like a daunting task.

People often think that the process of integrating a robot into a business will take many months. However, this is often untrue, especially with modern collaborative robots.

With the right robot and process, you can have a robot up and running within just a few days. This is even easier to achieve if you are using an integrated application kit for your specific task.

How can you put your robot into action in such a short amount of time?

Let's look at some of the basics and best practices for getting your robot up and running, as well as some of the common myths that might give you an overly conservative view of robot deployment time.

How to integrate a new robot into your business

Integrating a robot into your business is easier than you might think. But there are a few key things to keep in mind.

Here are some basic steps to help you integrate a robot:

-

Know what you want the robot to do. You may have various candidate tasks you want to automate with a robot. Start with a clear idea of the specific task you want the robot to complete first.

-

Determine the robot's limitations. Robots are great at doing the repetitive, consistent aspects of a task. But they have their limitations. Be clear on what a robot can and can't achieve.

-

Plan for training and support. Depending on your chosen robotic solution, you will probably need some training on how to use it. However, you can learn how to use some robots in less than an hour.

-

Consider the ROI. For many people, it's important to know how quickly the robot will "pay for itself." It's helpful to calculate the return on investment of the robot in your chosen task.

-

Plan realistic timelines. As with the introduction of any new technology, it's possible things won't go as smoothly as you'd like. When you set your timelines realistically, you reduce the impact of delays if they crop up, without being unnecessarily conservative.

With this in mind, it's now helpful to be aware of potential deployment time myths that might get in your way of following this process.

5 common deployment time myths about robots

There are a few common misconceptions about robotic deployment and how long it takes to add a robot to your business.

Here are 5 common deployment time myths about robots that you might be mistakenly believing:

1. Deployment takes months

In the past, robot deployment took many months. This is because conventional industrial robots required specialist robotic expertise. Solutions were almost always custom built because there were no off-the-shelf robot solutions as there are nowadays.

With new robot application kits, the deployment time is significantly shorter. The Robotiq Palletizing Solution, for example, can be deployed in just 2 days.

.jpg?width=729&name=Robotiq%20Palletizing%20Solution_PE%20Series_10%20(1).jpg)

2. Integration requires specialist skills and training

Conventional industrial robots often require significant specialist skills to deploy correctly, which meant long and arduous training. However, this is not true with collaborative robots and application kits.

With the newest robotic solutions, you can start using them with no prior knowledge or experience with robots. This means that you have to spend less time training people in robotics.

3. Automation will replace workers

People often think that automation will replace their existing workers. This can lead to worries that adding a robot will create lengthy administrative processes.

For most applications, adding a robot will not replace a worker. The robot simply takes some of the most repetitive tasks from your existing workforce, giving them more time to perform other tasks.

4. Robots require a lot of budget

You might be concerned that a new robot will eat into your existing budget, thus will require a lot of extra time and work to source that budget and convince management the robot is a good idea.

Most times, the cost of a robotic application kit is low enough that the decision is a "no brainer." It might be easier and quicker than you think to source the budget for it.

5. You'll need to redesign your entire process

With conventional automation solutions, it's common for companies to have to completely redesign parts of their manufacturing process to accommodate the robot. This is disruptive and takes a lot of time.

With collaborative robots, this is not usually the case. Their high versatility means you can integrate them easily alongside your existing processes.

How to choose the right robot for your needs

There are many potential applications to which you could apply a robot.

Every business has unique needs, so the perfect application for you will differ from other businesses.

When you have determined which application you want to automate with a robot, it's a good idea to start by identifying if there are any application kits available on the market for that application.

For example, if you are looking to improve your machining process, there are many ways to integrate a robot with a CNC machine. Some are more complex than others. However, a solution like the Robotiq Machine Tending Solution could be a good place to start.

If a specific application kit suits your needs, it probably makes sense to start with that application rather than opting for a more complex task as your first deployment.

The solution you choose will have a significant impact on your deployment time. The more off-the-shelf solutions usually are quicker to deploy and will cause you less stress. However, your situation might require extra steps that are only possible with a more custom solution.

If you are not sure which robotic application is right for you, get in touch with one of our team and they will help you out!

How long do you think it takes to deploy a robot? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, or the DoF professional robotics community.

Leave a comment