1D, 2D, 3D... What Kind of Vision System Should I Use for My Application?

Posted on Jul 04, 2016 in Vision Systems

5 min read time

Our brain is so used to see images in 3D, or 2D, that we tend to think this is what we need when shopping around for an automated vision system. You should know, however, that there are other options that you should consider.

1D Sensor if There’s a Conveyor

If you only need to measure a part that moves on a conveyor, a laser scanner or  a line-scan camera would be sufficient. It would be installed perpendicular to the part movement, on the side or on top of the conveyor. Laser scanners will use laser triangulation in order to take measurements: they throw a laser point or beam on the part, which in turn reflects the laser back into the sensor of the laser scanner. You can find more information on the various measurements possible and the way to achieve them properly on this page.

a line-scan camera would be sufficient. It would be installed perpendicular to the part movement, on the side or on top of the conveyor. Laser scanners will use laser triangulation in order to take measurements: they throw a laser point or beam on the part, which in turn reflects the laser back into the sensor of the laser scanner. You can find more information on the various measurements possible and the way to achieve them properly on this page.

If you need to inspect the surface of a part that is moving on the conveyor, a line-scan camera would be preferable: you would install it on top of the conveyor. You would gather “line images” and stitch them together in order to make a 2D image, and analyze this one. The linear camera is similar to a 2D camera, but with a sensor that has a single row of light-sensitive pixels.

Using a line scan camera, combined with the movement of the conveyor, has a tremendous advantage over a 2D camera: since the part moves, you would need to reduce the exposure time (amount of time in which the camera collects data) in order to avoid blur. By doing so, you would have a darker image, so if you wanted to have a proper one, you will need to add more light. If you are using a 2D camera, you will need to light up the whole area with sufficient light. If you only use a line-scan camera though, you could concentrate the light in this confined area, which is a lot easier. Also, getting a uniform light will be easier on a smaller surface.

Using the images from the line scan camera and the speed of the conveyor as a parameter, you could stitch those line images together and actually end up with 2D images (kind of an infinite width image, actually). You can find more info on this stitching process here.

2D Sensor – Do You Really Need Color and a Computer?

That being said, your application might still need a 2D camera. If you want to inspect an object that is not moving on a conveyor, as we have seen before, or if you want to use a camera for a pick and place operation, a 2D camera will probably meet your requirements. If this is your case, another question you need to ask yourself is if you need a color camera or if a black & white one would be sufficient. Again, our brain is so used to see in color, we tend to think we need the same for our camera. It is much simpler, though, to analyze black and white images. Using a color camera would leave you with more data, but would you know what to do with it? Using a black & white camera would still leave you with multiple shades of gray to work with. The processing time would be far less than with color images, the data transferring time would be decreased and the need for data storage also.

Another thing with 2D cameras: some cameras are sensors that capture the image and let you transfer it to a computer for extensive image processing. Some other cameras have the sensor and processor all embedded in the camera: these are called intelligent cameras or smart cameras. If you need basic image processing, for pick & place operations, for example, this type of camera will probably be sufficient, as you will not use funky image processing functions, and will not require to add a computer in order to do so.

If you buy a camera, it might come as an ‘all included’ package, including the camera, lens and processor, or you might have have the option to buy items separately. If this is the case, you will need to select a lens by determining what size of field of view you will need, what resolution is needed, how far from the inspected object the camera will be, etc. Depending on your application, the camera vendor should be able to help you with the best equipment and optical adjustment, but since it is always good to have some basic knowledge, it is good to know this simple rule when selecting a lens to use with a 2D camera.

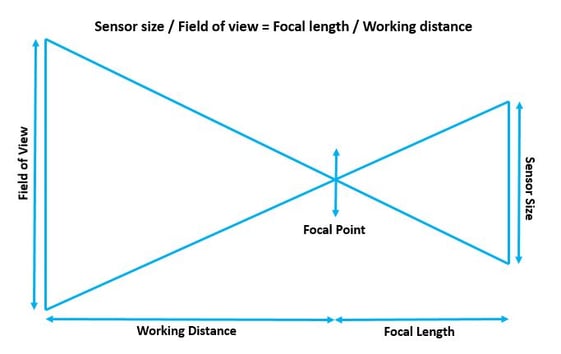

Following the similar triangles rules, use this formula:

Sensor size / Field of view = Focal length / Working distance

Sensor size: Actual size of the CCD sensor inside the camera. Various dimensions are available, ranging from ¼” to 1.2”. The sensor size vs its name is rather confusing: a 2/3” sensor will actually measure 8.6 x 6.6 mm (if you’re interested in historical reasons for the 2/3” name, consult this page).

Field of view: The physical size of the area you will be looking at with your camera. This area will probably be rectangular, since most CCDs are rectangular. Typically, it will follow a 4:3 rule, so if you have 12cm in width, you will have 9 cm in height.

Focal length: The ‘strength’ of the light convergence. 25mm, 50mm, etc. The focal length is inversely proportional to the field of view, so an image taken with a 50mm lens will be more zoomed than if it were taken with a 25mm lens.

Working distance: Physical distance from the sensors to the object you want to look at.

3D (And This Time It Doesn’t Mean Dull, Dirty and Dangerous)

For other kinds of application, like reverse engineering or metrology, you might need a 3D scanner. The 3D scanners available on the market use various techniques: laser triangulation, shape from shading, structured lighting, etc. Scanning in 3D will leave you with a tremendous load of data, so make sure you need all this information before jumping in and buying a 3D scanner. You will also need to select the appropriate scanner based on the application you have in mind: some scanners will be very precise in their measurements, but their field of view will only be a few centimeters wide. Other scanners will scan large areas at a time, but will surely be less precise in their measurements.

So what is it going to be for your application: 1D, 2D or 3D?

Stay tuned for the upcoming article on how to configure your 2D vision system.

Leave a comment