Planning for Life Cycle Costs When Implementing Robotics

The manufacturing industry is always changing. Companies adapt to everything from changes in the political climate and the economy to new technological and safety standards. A manufacturing plant today looks completely different from those of 50 years ago.

Labor, a plant’s very lifeblood, is experiencing some of the most noticeable changes. In industries facing rising labor costs and the need for increased specialization, robots now offer a cheap and reliable alternative to human employees.

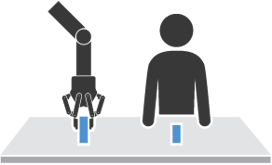

Although the switch to robots for manufacturing comes with some obvious perks, like less manual labor and healthcare savings, it can also have its drawbacks, such as requiring a large initial investment. Thankfully, cobots -- robots that work collaboratively alongside humans to improve company efficiency -- only cost about one year’s salary and can be much more easily programmed than industrial robots.

Know the True Life Cycle of Your Cobot

If you want to integrate some form of robot automation into your manufacturing, you have quite a bit of work ahead of you. Similar to how other businesses calculate their new hardware costs, you’ll have to determine the true life cycle cost of the robot.

If you want to integrate some form of robot automation into your manufacturing, you have quite a bit of work ahead of you. Similar to how other businesses calculate their new hardware costs, you’ll have to determine the true life cycle cost of the robot.

This figure represents the total amount of money you can expect to put into the robot over its expected operating period. This starts at the initial purchase and extends to cover the cobot itself, plus the gripper, vision system, monitoring system, etc.. If properly cared for, you can expect to get at least four of years of use out of your cobot before refurbishing may be needed.

The main goal of this endeavor is to determine what costs you can expect when implementing the robot. If you’re specifically looking to cut costs, you can also use this metric to compare paying for a robot versus the equivalent human labor. To start your calculations, use this simple formula:

True Life Cycle Cost = Baseline Cost + Investment + Potential Scenarios, but you should also figure in the savings and ROI your cobot can provide as well.

In some of these figures, like energy costs and maintenance, you’ll have to consider the kind of robot you’re implementing. Industrial robots tend to consume more power than cobots, for example. You should also factor in the estimated lifespan of the robot to get an accurate figure. And, although it may seem difficult, these calculations are necessary to evaluate your potential ROI.

Now that you’ve got the basic idea, let’s run through the details of this calculation.

Counting the Costs

When brand-new, the typical collaborative robot — with controllers and other peripherals — costs between $50,000 and $80,000. Reconditioned models go for $25,000 to $40,000. For a smaller business, these costs may be hard to stomach up-front. But with the right balance, they’ll pay for themselves over their full lifetime.

When brand-new, the typical collaborative robot — with controllers and other peripherals — costs between $50,000 and $80,000. Reconditioned models go for $25,000 to $40,000. For a smaller business, these costs may be hard to stomach up-front. But with the right balance, they’ll pay for themselves over their full lifetime.

Your next job is to determine how much you’d pay for the power required to run the robot. Collaborative robots don’t consume much power at all, so this will be a small part of the overall costs of implementation.

Maintenance Cycles

Maintenance costs are based on cycles completed, and are actually more predictable than you might think. Experts recommend that you conduct checks daily, monthly and yearly depending on how often you use the robot. The checks assume the robot will spend 3,840 hours per year performing factory operations. Checking sensors, cleaning components and performing tune-ups all fall under this category and cost time and money to perform.

Maintenance costs are based on cycles completed, and are actually more predictable than you might think. Experts recommend that you conduct checks daily, monthly and yearly depending on how often you use the robot. The checks assume the robot will spend 3,840 hours per year performing factory operations. Checking sensors, cleaning components and performing tune-ups all fall under this category and cost time and money to perform.

Replacement parts also fall into this category. Budget some money for this, but focus your efforts on preventative maintenance. While breakdowns are inevitable, a good maintenance schedule can greatly extend the life expectancy of your robot.

Additional Factors

The “additional factors” category is hard to define, but it boils down to incidentals not covered by any of the others. Here is where you would factor in costs such as seasonal demand changes, issues in other parts of the factory and other problems. As with maintenance, these costs could be unpredictable.

The Final Decision

Now that you’ve compiled the figures, all that’s left is to make a decision based on your findings. How does the cost of running your robotic employee measure up to a human? Does the savings and reduction of production line errors make the initial lump payment worth it? Can you see yourself still needing the robot in four to eight years?

Manufacturing is an ever-changing field that requires the adoption of new standards and practices. As more and more specialized robotic machines enter the market and workforce, companies must make sure they consider their true costs before investing.

Leave a comment