New eBook on Collaborative Robot Risk Assessment

Posted on Aug 13, 2015 in Collaborative Robots

2 min read time

If you have been in the robotic or industrial world you have probably already heard about risk assessments. This process is of vital importance to make sure your employees are working in a safe environment while using machinery. In the particular case of collaborative robots, the safety requirements are a big concern. However, the different components of these requirements are sometimes hard to coordinate. This is why we put together an eBook on the subject to give you the tools necessary to understand what a risk assessment process is.

What is a Standard?

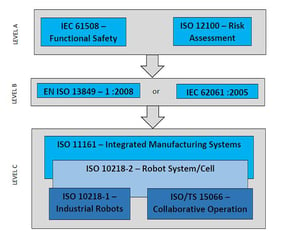

A risk assessment process is described by different standards and in most cases, these norms have to be met to legally operate a robot. So before installing your robot, you need to understand what a standard is and which ones apply to your particular application. This part of the eBook explains what different standards might be applied to achieve a safe robotic cell.

We also introduce the new ISO/TS 15066 technical standard that is focused on collaborative operations. Since this type of robot is relatively new, no real standard has yet been released. This standard is scheduled for and will (hopefully) be released by the end of the year.

Manufacturer Certification

There is a common misunderstanding in the robotic world (especially in collaborative robotics) which is that: if the robot is safe, the application is safe. This is totally wrong. A robotic application has to be certified as a whole (robot, tool, object, motions, etc.). So even if a robot is considered ''safe'' or collaborative, there are still other requirements that have to be fulfill before saying that the application is safe.

All robot components have to reach a certain level of safety to be used alongside humans. This is called a ''performance requirement'' for each component. This requirement is classified in a specific nomenclature and is based on the risk of failure and the number of redundancies that are available in the component’s safety features. In other word the performance requirement is how safe a device can be. Collaborative robots need to reach a certain level to be deployed in a robotic cell. This part of the eBook explains how manufacturers certify their products.

Risk Assessment

Questions such as: What is a risk assessment? Why do a risk assessment? What is a risk assessment process? What is a risk assessment for a collaborative application? and many more are answered in this part of the eBook. This part of the eBook really goes into deeper detail of what a risk assessment process really is and how to perform it. There is also greater specification on what are the different types of collaborative applications (which most of the time people are unclear about).

I highly encourage you to get all the information you can from this document. Then get out there and look for more ways to make your robotic cell as safe as possible. To read the entire eBook click on the link below.

Leave a comment