Using Feedback from the 2-Finger Adaptive Robot Gripper

by David Castonguay.

Last updated on Dec 12, 2024

Posted on May 23, 2012 in Robot Grippers

2 min read time

Posted on May 23, 2012 in Robot Grippers

2 min read time

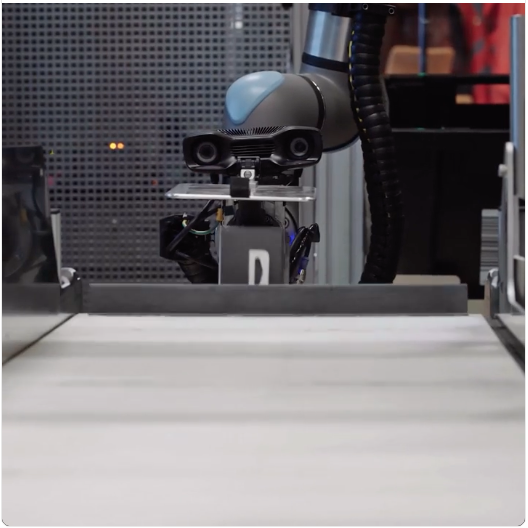

This article explores how feedback from the 2-Finger Adaptive Gripper might be used in industrial applications.

This article explores how feedback from the 2-Finger Adaptive Gripper might be used in industrial applications.

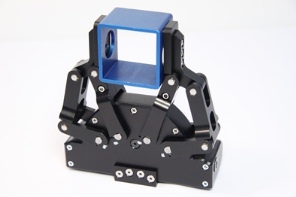

Let's start by listing a few types of feedback received by our 2-Finger Gripper:

- The incremental encoder value for opening and closing.

- The motor current.

- Object detection and error messages.

Now let's look a little closer at the application of these feedback items.

Encoder Value:

- Like the 3-Finger Robot Gripper, the 2-Finger Gripper has a feature which is called partial opening. This feature has two input parameters: Opening Limit and Closing Limit. In order to optimize cycle time, this feature can be set to the object's dimensions through the encoder value, which is ranged from 0 to 255. By doing so, the Gripper will respect these opening and closing limits, thus reducing cycle time by not having to fully open or close. Speed and force must still be set accordingly to your application.

- The encoder value can also be used as a qualitative way to measure the same object or to verify whether the Robot Gripper has picked a part in the desired way.

Motor Current:

- The motor current can be used to monitor the energy consumed in a complete cycle. This might be useful for integrators in the design of a robot cell. By knowing the motor current, power supplies and their related protection devices can be appropriately dimensioned.

- The motor current value, ranged from 0 to 255, can be used in a qualitative way to know what final force will be applied by the fingers to the object. The 2-Finger Gripper also has an auto-locking mechanism. This means that the motor doesn't need to apply force continuously on the object to maintain the designated final force. Care must be taken when using the motor current in this way. Tests must be performed with different force settings to be sure the Gripper doesn't damage any fragile parts.

Object Detection and Error Messages:

- The 2-Finger Gripper is able to detect whether an object has been picked up or not. This feedback can be very helpful when used in conjunction with a teach pendant program. In fact, recognition of object detection can be used as a conditional statement in a routine.

- The 2-Finger Gripper gives error messages. Based on the seriousness of these messages, the robot may be programmed in such a way that it behaves safely when Gripper errors occur. See the list of error messages in the user manual to integrate them properly into your robot program.

Now that you have some ideas about how the Gripper feedback can be used with your robot, go ahead an experiment till you find the settings that work best for your application!

.jpg)

Leave a comment