What You Must Know Before Choosing a Screw Fastening Robot

Are you excited to get started with assembly automation? Perhaps you can already imagine how a screw fastening robot will help to improve your whole assembly line.

Before you start deploying the robot, there are a few important things you should be aware of.

Screw fastening is an extremely common task. It is one of the most common fastening methods in assembly. Even small changes in the screwdriving process can have significant effects on your assembly accuracy.

A robot screwdriver can be a highly-effective tool. It helps to improve the quality and consistency of your fastening task.

But screw fastening can also be a complex task to automate. With the right approach — and the right robotic solution — you can ensure that you make the right decisions for your unique manufacturing business.

Let's look at some things you should know before you pick a screw fastening solution.

How to make better choices when considering robotic fastening

A common misconception people have when they first decide to automate a fastening process is that "the robot will be able to do everything."

You might be imagining a robot kitted out with many accessories and sensors. You imagine the robot moving quickly around its cell. Changing screw types all the time. Flipping the workpiece around to drive screws into every available surface.

Although it's possible to automate almost any screw fastening task, it's important to be practical.

People are sometimes unrealistic in their expectations of what the robot will be able to achieve. They set their sights on completely automating a complex fastening process. Unfortunately, these high expectations often lead to their robots gathering dust in a cupboard.

Likely, you don't have the time, expertise, or energy to integrate a very complex robotic fastening cell. But there is usually no need to overcomplicate things.

A simple fastening robot can be extremely effective.

7 things you must know before choosing a robot screwdriver

How can you make sure that you are choosing the right screwdriving solution for you?

It helps to have a bit of background knowledge about robotic fastening. The strengths and weaknesses of robotic automation are sometimes different from what new users expect.

Here are 7 things you should be aware of before you start using screw fastening automation:

1. Similar-looking solutions are often very different

You can find several different solutions for screw fastening on the market. If you are not so familiar with robotics, these solutions might look similar to you.

Even similar-looking robotic systems offer hugely different user experiences. You can think of them like as being like different cellphone or laptop brands — despite apparent physical similarities, some are much easier to use than others.

2. Programming is an "invisible" important factor

One major difference between different screw fastening solutions is programming. This is how you will instruct your robot to perform your particular screwdriving task.

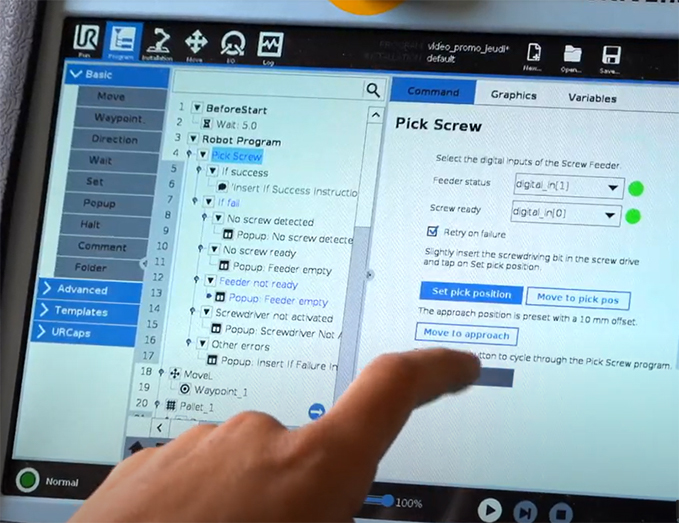

Some robotic solutions offer a very simple programming interface for fastening. The Robotiq Screwdriving Solution, for example, includes a custom application plugin that allows you to program the task in just a few clicks. Many other solutions offer an overly complex programming interface.

You won't be able to see this until you try using the robot for yourself, or at least see it being programmed.

3. Simplicity is key

It's always a good idea to keep your screw fastening task as simple as possible when you are automating it with a robot. This ensures that you will get your robot up and running as soon as possible, with less chance for error.

A task that is simple for a robot is not the same as one that is simple for a human worker. Learn what makes a screwdriving task simple for a robot.

4. The robot may be slower… but that's okay

We often imagine that robots will move very quickly. Perhaps this is because we are so familiar with the videos of impressive high-speed assembly robots in YouTube videos.

If you are using collaborative robots for your screw fastening, the robot will likely move quite slowly… slower than your human workers. However, this is okay. Most productivity gains come from moving people away from the screwdriving task and onto other tasks, not from the robot being super-fast itself.

5. Quality and consistency are the big benefits

Speed and increased throughput are also less important than people think. For any robot — whatever speed it moves at — the biggest benefits come from increased quality and consistency.

Even a 1% failure rate in screwdriving (which is actually quite good for manual fastening) can generate tens of thousands of bad products over the course of a day. A robot will significantly reduce this failure rate.

6. Your fastening task should be high impact

When choosing which screw fastening task to automate, try to ensure that it meets these two criteria:

- The task is simple. For example, the workpiece can be held with a single fixture and all the screws are on the same face.

- The task is high impact. Automating it with a robot will give immediate and obvious benefits to your assembly process.

7. You are not alone. Help is available.

Finally, it's important to remember that screw fastening assembly can be challenging the first time you automate it. However, you don't have to do it alone.

Help is available to make your robot deployment as easy and pain-free as possible. You can reach out to our team directly or post a question on the DoF robotics community forum.

How to start your robot fastening project on the right foot

What's the best first step for starting your robotic fastening project?

One useful resource is our free eBook How to Automate a Screwdriving Cell. This gives you a clear, step-by-step guide to setting up your first fastening robot.

To find out more about the Robotiq Screwdriving Solution, check out our solutions page

What questions do you have about screw fastening automation? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, or the DoF professional robotics community.

Leave a comment