What is the Relation Between Sharks and Robots ?

Posted on Sep 14, 2015 in Robots

3 min read time

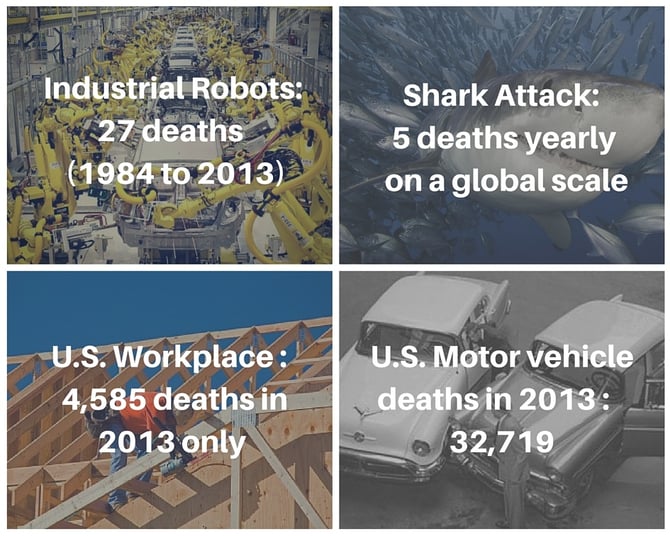

In the last couple of months I've been confronted with people who were totally against the introduction of robots in their workplaces, because of the perceived view that these machines are dangerous. I was actually surprised! I then decided that a bit of research was needed to find out if robots were really risky or if this was some kind of urban legend that was created by a fear of robots. I quickly realize that industrial robots are like sharks, they are not all that dangerous, but people still perceive them as dangerous.

In fact according to statistics you have a greater chance of having a fatal car accident than getting killed by a robot. Yet, I don't know a lot of people who stay home because they fear they could have a car accident. Though I do know a lot of people that don't want to put their toes in the ocean because they are afraid of sharks.

So the bottom line is: if it happens at a very, very, very low rate, accidents are not considered all that dangerous. Am I wrong? You have a greater chance of getting killed by a hippopotamus (29,000 deaths each year) than being a victim of a shark attack, so hippopotamuses are dangerous. Actually, you have more chance of a fatal injury while working on your roof (approx 127 deaths yearly in the U.S.) than getting injured by a robot, however, most roofers still work without ropes.

So according to these statistics, there is not a particularly high danger of injury associated with using a robot in your plant. If you are still worried about the safety of your employees, after their shift you should transport them in crash proof vehicles or maybe driverless cars (their track record is pretty good) and everyone should wear full body armor while driving.

What is a risk?

A risk (from an industrial point of view) is the consideration of three main factors: the severity of the injury, the probability of avoidance of injury and the probability of occurrence of injury. Since there are various ways to interpret an accident, it is kind of tough to analyze if a robot can be more dangerous than other industrial applications.

However, what can be said is that most accidents related to robots are done while commissioning the robot. At that moment the robot, and we are talking about robots that deal with heavy loads, is in direct contact with humans, as well as when safety devices have sometimes not even been installed yet in the robotic cell. This greatly increases the probability of an accident occurring and reduces the probability of being able to avoid an erratic robot motion that can cause severe injury to workers.

The same things apply to shark attacks. In fact, 50% of shark attacks are on surfers. When you surf, you do increase your exposure and once the shark has spotted you, it's hard to avoid a shark. Anyway, I am not an expert on sharks or in surfing but the bottom line is, when you are closer to the danger you have more risk of injury.

The other side of the coin

Notice that I am not saying robots are safe and sharks are friendly. Historically, a lot of procedures and precautions have been put in place to avoid such accidents. Safe guarding has been introduced to plants to separate the robots and workers. These precautions are a direct consequence of the few accidents caused by robots. That being said, industrial robots must also meet safety regulations and you have to install protection or prove that the use of the robot is safe for all humans, period, regardless of its use: commissioning, programming, routine, etc.

The case with new collaborative robots, i.e. robots that are designed to be used alongside workers without any additional safety features, is proof that robots are technologically ready to be introduced to human-like applications. Their safety devices are more accurate and allow all movement to be stopped when they read a small impact. This means a safe working environment using robots.

If you still have concerns about introducing a robot into your plant, you should probably take a look at the document we have created on collaborative robot risk assessments. This is basically a resource to help you figure out how to introduce a collaborative robot into your plant while at the same time keeping your employees safe.

Leave a comment