PAL-AX10 v1.3 Error: Please use the safeguard reset before starting the linear axis

How to clear the safeguard reset error when using the PAL-AX10 linear axis

When starting the PAL-AX10 v1.3 linear axis, you may encounter the error message:

Please use the safeguard reset before starting the linear axis

This error occurs because the system requires a safeguard reset before the axis can be initialized. This safety step ensures the robot environment is secure before movement.

If the Error Persists

If you have already double-checked the Safeguard Reset wiring and Safety I/O configurations but still cannot clear the error:

-

The safeguard reset is primarily handled by the wiring inside the UR controller.

-

However, a second validation check is performed by the Siemens PLC.

-

If there is a mismatch between:

-

the URCap check (Festo Drive), and

-

the Siemens PLC check,

the safeguard reset error will remain active.

-

In other words: even if the wiring is correct, a disagreement between the UR and PLC validation may prevent the error from clearing.

Troubleshooting Steps

-

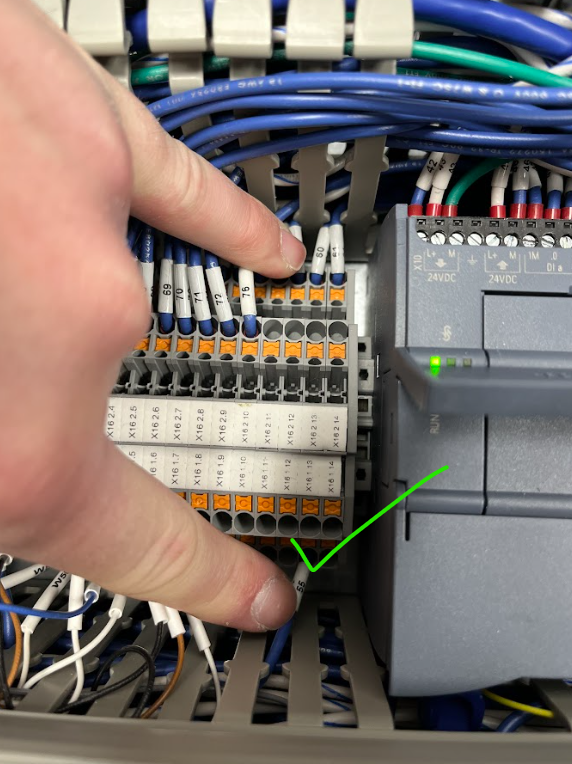

Check Siemens PLC LEDs

-

Press the pallet sensors:

-

Left sensors → DI0 & DI1 should light up.

-

Right sensors → DI2 & DI3 should light up.

-

-

✅ If these LEDs light up, proceed to the next step.

-

❌ If they do not light up, check PLC power and confirm the RUN light is green.

-

-

Check the Safety Status LED (DI4b)

-

Locate the Safety Status LED on the Siemens PLC.

-

DI4b must be ON.

-

❌ If the LED is OFF, there is a wiring issue with the safety status check.

-

Solution: Check the 24V Line with a Voltmeter

If the above checks fail, confirm the 24V wiring between the Safety Relay and the Siemens PLC:

-

Probe the Siemens Safety Relay at Port 2, Wire 55.

-

You should measure 24V.

-

(Probing in continuity mode also works.)

-

-

Probe the PLC terminal X16, pin 1.13 (Wires 55/60).

-

You should still measure 24V.

-

(Probing in continuity mode also works.)

-

If 24V is not present at one of these points, the issue is in the wiring between the Safety Relay and the Siemens PLC.

-

Finally, probe between Wire 60 on terminal X16 1.13 and DI4b on the Siemens PLC.

-

At this point, you may discover that one of the wires is not connected to the correct terminal.

-

Ensure all wires are securely fastened into the correct ports and terminals.

-

::note=Please contact the support team if you still cannot figure out the issue. support@robotiq.com