Buying a Robot is Cheaper Than Outsourcing to China

Posted on Mar 18, 2015 in Robots

7 min read time

The goal of every manufacturing process is to answer to customer needs with the lowest possible cost. Quite simple right? Some manufacturers are facing a point where they need to outsource their manufacturing process to reduce their cost and be able to answer customers demands. When the outsourcing is done locally, there is nothing to worry about. However, more often than not, outsourcing is done overseas in order to dramatically reduce manufacturing costs. Even with transportation fees, it is often believed that outsourcing overseas remains cheaper, because of the low labor costs. Here is how you can increase your production rate while keeping your production in-house and keeping your employee's jobs safe.

The first question we get asked when customers are looking for robotic devices is: How much? For sure, it is all about money at the end of the day. However, keeping your production locally, while increasing your production rate and enhancing your product quality can also be part of the equation. This article will discuss the long term advantages of a robotic cell in terms of costs and ROI. I have included an example to help you understand the different steps of the analysis. The calculation will show you that introducing a robot is cheaper than paying for an employee overseas and this analysis does not even include all the different problems associated with overseas operations and transportation.

Outsourcing

America and Europe are fighting to survive in a hyper-competitive global market. Even though there are constant improvements in emerging countries' product quality, there is also increasing labor costs. It is time to stop and see if outsourcing is a real option. With all the different obstacles that outsourcing proposes you may want to keep your production local. Some problems may be related to:

-

Transportation Costs

-

Transportation Delay (Longer Delivery Time)

-

Quality Problems

-

No Real-time Manufacturing Control

-

No Ability for Quick Process Change

According to Forbes Magazine ''Buy a Robot and Save America'', the average wage of a Chinese worker is $3/h. Even with all the transportation fees, it remains a lot cheaper than using the local workforce at $25-$30/h. However, cost does not rule the whole problem, you have to consider other aspects. To survive in the global marketplace, companies must focus on:

-

Productivity

-

Supply Chain Cost and Time

-

Product Quality

All aspects that can be achieved by introducing a robot into your workshop.

Cost of a Robotic Cell

We have recently written a blog post on the return on investment (ROI) for a robotic cell. This post will give you more information on what to look for in your robotic cell.

To evaluate the price of a robotic cell on a long term horizon a couple of aspects have to be considered. First, what is the actual yearly cost to run your application. Then the investment of the robotic cell, its running cost and finally the potential production cost. All these calculations have already been explored in a past article.

Operating costs haven't been discussed since this data is used for long term analyzes, we thought it wasn't pertinent for the ROI calculation. The basic operating costs of a robotic cell are mostly related to maintenance.

Consider a yearly maintenance figure (mainly lubrication) of about $300-500.

Example:

As a baseline, the yearly maintenance cost is calculated considering several different costs; related mainly to your labor, but should include other factors like erroneous production/scrap and replaceable equipment/jigs or tool bits.

Yearly Cost = Employee [Unit] * Shift [Unit] * Salary [$] + Downtime [$] + Scrap [$] + Jig [$]

Yearly Cost = $125,000

------

The starting investment will include the robot and all its peripherals. The integration cost, transportation fees, taxes and training should also be included in this calculation.

Starting Investment = Robot [$] + Gripper [$] + Vision system [$] + ...

Starting Investment = $49,100

------

This analysis will give you an estimate of the potential savings that can be achieved by the robot.

Potential Scenario = Employee [Unit] * Shift [Unit] * Salary [$] + Downtime [$] + Scrap [$] + Jig [$]

Potential Scenario = $63,000

------

For this example the yearly maintenance costs has been calculated at about $300.

Long Term Analysis

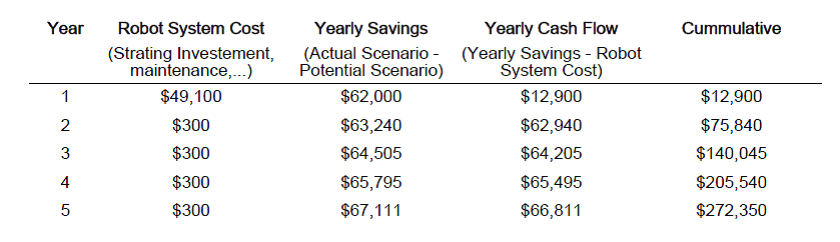

To help you to analyze all these numbers, we have put together a table. This will make it easier to visualize the long term impact of a robot in your workshop, preferably you should analyze the situation with a 5 years horizon.

-

Robot System Cost (Calculated in the previous section).

-

Yearly Savings (Actual Scenario Cost - Potential Scenario Cost). This parameter should consider inflation.

-

Yearly Cash Flow (Yearly Savings - Robot System Costs).

-

Cumulative Savings (Summation of the Yearly Cash Flow).

Example:

So with a worker doing jobs on 2 different machines split over 2 different shifts. Each worker with a salary of $50,000 yearly and including a 2% inflation rate yearly. The following numbers give you an idea of the cumulative advantage of implementing a robot into your workshop.

So with a reimbursement of the robot cost in less than a year (9.6 months); we can see that before the end of year 1, savings are accruing from the robotic cell. By the end of the observation window, a total saving of $272,350 have accumulated after 5 years.

To have a better idea of the robot hourly rate, the following calculation can be made:

Starting Investment = $49,100

Maintenance Cost = $300 * 5 [years] = $1,500

Robot Hourly Rate = ($49,100 + $1,500) = $50,600 / 20,000 hrs = $2.53/hrs

So on one hand you are saving money by introducing a robot to your work floor. In this particular scenario a total of $272,350. And on the other hand, your robot isn't very expensive to run. In fact at $2.53/hr, it is cheaper than the average developing country employee.

Conclusion

What have we learned here. First of all, introducing a robot into a plant is really cost efficient. In other words, it is a wise move to introduce a robotic cell to your plant, since it will allow you to save money. Second, the cost of a robot is way lower than a developing world worker. Third, by introducing a robot into a local shop, you do keep your employees near and do not send valuable revenue overseas. You can manage your production and save on transportation fees. The fact of introducing a robot into a plant does not threaten jobs. In fact, in some cases, they are creating them. I hope that this article gives you a better idea of the potential savings that can be achieved by using a robot. I should also say that the example used in the past two articles is for a low price robot with minimal protection and devices, however, doing the calculation with a bigger robot and a wider range of accessories will give you similar results. It is possible to save money with a robotic cell.

Leave a comment