Top 5 Challenges of Robotic Welding Programming

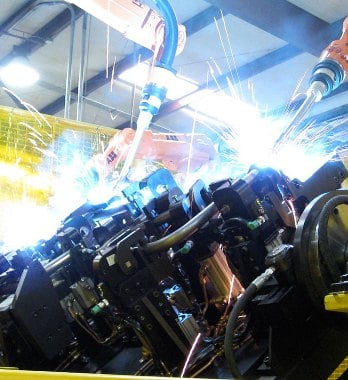

Posted on Feb 08, 2013 in Robotic Welding

2 min read time

Until now, robotic welding has been restricted to high production applications because of the length of time it takes to program a change in product lines. Set up robot welder required in-depth knowledge in programming and the actual methods are not intuitive even for programmers. Here is the top 5 of robotic welding programming challenges.

To be efficient and productive, programmers must learn how to: the length of time it takes to program a change in product lines. Set up robot welder required in-depth knowledge in programming and the actual methods are not intuitive even for programmers. Here is the top 5 of robotic welding programming challenges.

Work with programming tools from various robot manufacturers.Computer control systems for robots vary from manufacturer to manufacturer and model to model. Although a teach pendant can be used to move the robot welder around with a joystick or arrows; it is not an intuitive method of teaching the robot because each linkage can only be moved one axis at a time.

Work with programming tools from various robot manufacturers.Computer control systems for robots vary from manufacturer to manufacturer and model to model. Although a teach pendant can be used to move the robot welder around with a joystick or arrows; it is not an intuitive method of teaching the robot because each linkage can only be moved one axis at a time. - Program the path plan and trajectory of each linkage. Programming a welding robot would be easier if only the tip of the robot arm, or the end-effector position, had to be considered. However, the positioning of each joint and segment of the arm needs to be programmed to consider changes in arcs and joint angles.

- Designate the accelerations and decelerations of each linkage. The speed for each coordinated movement needs to be specified with an appropriate acceleration and deceleration of each joint.

- Define sensor inputs and outputs. Additional programming needs to be learned so a robot can use sensors as inputs and outputs as a binary signal to select robot programs and perform specific actions.

- Gain experience by trial and error. Programming a robot welder well could take years to master and training requires a significant amount of trial and error.

When programming a robot become intuitive

At Automate 2013, Robotiq gave an insight a new robot accessory, Kinetiq Teaching, which allows the welders to freely the robot arm through its workflow and adjust welding parameters on-the-fly via the teach pendant, then test it live. This process results in a simple and intuitive approach to programming welding trajectories.

See the video and visit our website for more about this robotic welding solution.

Leave a comment