Best Practices When Using the Force Control Node

The following document provides guidelines and best practices for using the Robotiq Force Copilot software, specifically focusing on the force control node.

This software enables precise force control applications, such as sanding, polishing, assembly, and more. It offers adjustable parameters that can be fine-tuned to achieve the desired behavior.

For comprehensive training on the Force Copilot software, visit our e-learning platform at https://elearning.robotiq.com/.

Force Control Node

The force control node is a key component of the Force Copilot software. It allows for real-time control of the force applied by the robot.

Feature Selection

- Base: Forces are applied relative to the robot's base coordinate system.

- Tool: Forces are applied relative to the robot's end effector.

- Motion: Forces are applied relative to the direction of motion, with the x-direction representing the motion direction.

- For this document, we will focus on the Tool option.

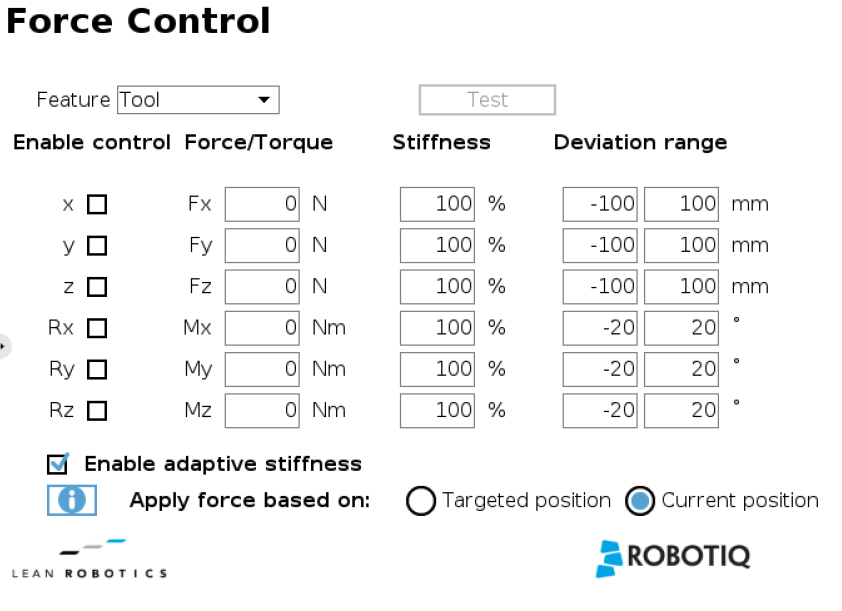

Adjustable Parameters

- Enable Control: Select the specific axis on which force control should be applied.

- Force/Torque: Define the force or torque that should be applied in the selected axis.

- Stiffness: Control the rigidity of the force control process and the speed of force compensation.

- Adjust the stiffness setting based on the desired behavior, ensuring it is not too low (Tool bouncing on the surface) or too high (causing excessive pressure on the surface or tool getting away from the surface).

- Deviation Range: Limit the distance of force compensation during force control to ensure the robot stays within a defined trajectory. This parameter is applicable only when using the Targeted Position mode.

- Enable Adaptive Stiffness: Enable automatic adjustment of stiffness based on force readings.

- The robot continuously adjusts the stiffness according to the detected forces.

- Note that this mode may not be suitable for all applications. If the desired results are not achieved, use manual stiffness adjustment and make necessary adjustments.

- Apply Force Based On:

- Targeted Position: Adjusts based on the detected forces and the initially taught trajectory. It considers the shape of the trajectory and adjusts accordingly. This mode is recommended for irregular surfaces.

- Current Position: Relies on the detected forces to adjust the trajectory, ignoring variations in the taught z position (considering the force is applied in the tool's z-axis). This mode is typically suitable for flat surfaces.

- You can test both modes in your application to see which one gives you better results.

Types of Movements

Within the force control node, three types of movements are allowed, enabling precise force control applications:

- Path: Teach a trajectory by manually guiding the robot's movements by hand. Each movement is recorded and can be replayed with force application.

- Path Generator: Generate trajectories to cover large surfaces by defining only a few waypoints. Particularly useful for sanding cabinet doors, countertops, or similar large surfaces.

- Multipoint Path: Allows programming linear and curved trajectories similar to UR's traditional waypoint programming.

Best Practices

- Avoid Large and Rapid Angular Movements: Force control may not be suitable for applications requiring large and rapid angular movements, such as rounding sharp corners. Quick angular movements make it challenging to maintain consistent contact and applied force.

- Minimum Force Requirement and Vibration Considerations: Applications such as sanding or processes generating vibrations that will affect the force control precision. Vibrations can be interpreted as applied forces by the sensor, affecting force control accuracy. For example, sanding applications require a minimum force of 20 N to get reliable results. If force variations exceed the desired applied force, achieving precise force control becomes challenging.

Conclusion

Note that force control applications can be challenging and time-consuming to program. However, with the Robotiq Force Copilot software, you have powerful capabilities for achieving precise force control tasks. By selecting the appropriate applied force based on mode and considering the type of surface, you can optimize your results.

Need help? Contact Robotiq Support

Updated: January 2026