Payload transition strategies for palletizing

Context

When picking and lifting a product the palletizing robot has to transfer the weight of the product from the surface where it is resting to the robot flange. Then when releasing the product the palletizing robot has to transfer the weight of the product from the flange to the surface of the stack.

This weight transfer takes sometime and in most cases it occurs in a non linear manner. If during this transition period the robot feels forces that do not reflect its payload settings, the robot will fall in protective stop.

This article presents a way to program a pick and release to reduce the risk of having protective stops during payload transition. A most reliable method is presented (the one that takes to most time) with some possible compromise to that can be done to save time.

::info=Reducing the maximum allowed TCP force in installation safety settings increases the risk of protective stops (It is often desirable to limit the TCP force for collaborative integration).

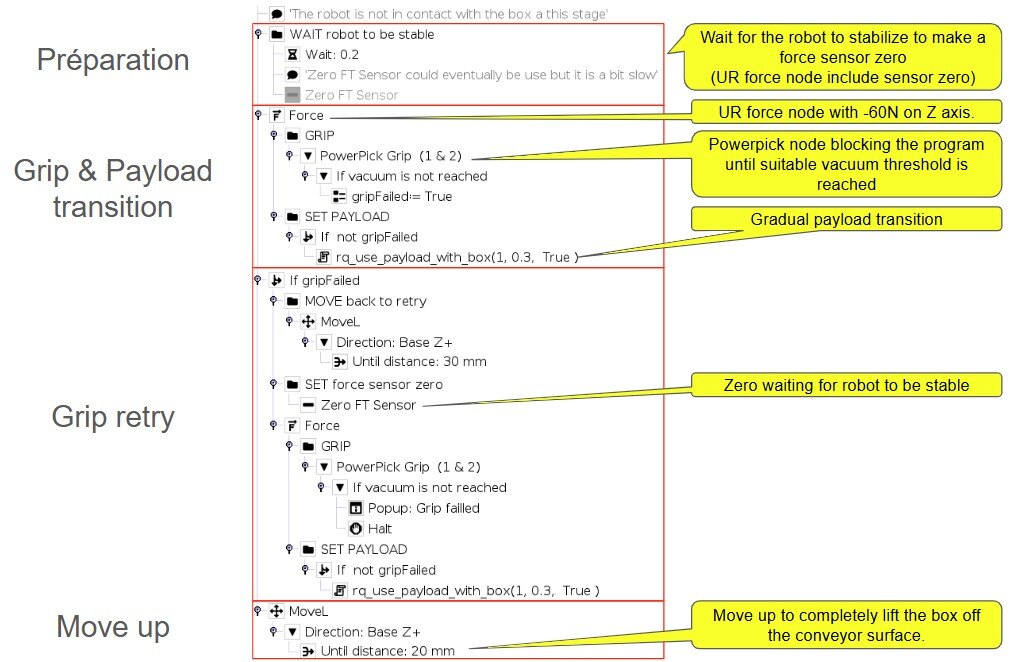

Payload transition at pick

Important :

To have this strategy working, the pick position must be set so that the cups are not compressed on the box. It must be just above the box surface.

Note : This method include a strategy to retry to pick the box if the first tentative fails.

Node settings:

- Force: Frame, feature base, Z axis, -60N, 150mm/s

- Zero FT sensor : Wait until sensor reading is steady

- moveL: 200mm/s, 200mm/s2

Note : Starting 5.20.0 polyscope will be able to automatically set speed and acceleration to avoid protective stop. This feature is called optimove. Use optimove when it will be available.

How much time does it takes ?

- ~0.2s to make the zero in stable condition

- ~0.5s to travel to the surface

- ~0.5s to reach the vacuum threshold

- 0.3s to make the payload transition

- ~0.5s to move out of the conveyor

Maximum duration: ~2s

If you need to save time in the grip and release process. You can progressively remove part of the strategy until you get a good compromise between speed and stability.

- (-0.7s) Set the the pick position with the cup directly compressed on the box, do not wait for the robot to stabilize to make the zero of the force sensor and set force node force to 0N.

Important :The draw back is that the root with collide with the box (pick position with cup compressed) everytime it picks a box on the conveyor. This may wear joint and reduce robot life time.

- (~0.2s) Reduce the vacuum threshold to reduce time spend in vacuum node.

Important

The draw back of this is that the grip quality will go worst.

- (~0.2s) Reduce payload transition time

Important:The draw back is that the robot may not have enough time to clear payload transition forces in the force node. If residual forces are too high the robot can trigger a protective stop.

- (0.5s) Remove the final vertical moveL or use faster speed and acceleration.

Important : The draw back is that the robot will start its trajectory with a high acceleration (This is how our palletizing trajectories works at the moment) and this can ease protective stop if residual forces are present.

Minimum duration: 0.4s

Payload transition at release

Important :Make sure pallet height and box height are correct. If pallet height is not stable, use the "variable height" option of pallet menu.

Important : Make sure box height is calculated from an average.

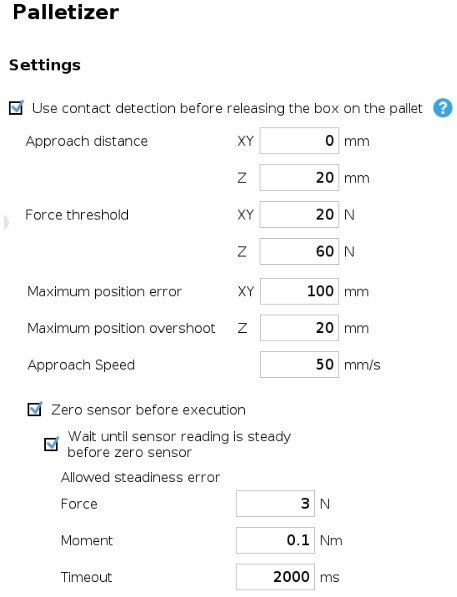

"Use contact detection before releasing the box on the pallet" palletizer node settings option is necessary for this release method. This makes sure the robot always place the box with the same manner on the stack. It makes the release process more repeatable and therefore more stable. This option also improve the build quality of the stack. Without it, boxes can be release from too high an fall at random position.

Contact detection settings:

- Approach distance Z: 20mm (What matter is that the robot is not in contact with the pallet when stating contact detection process. Adjust depending on box height variation)

- Force threshold Z: 60N

- Maximum position overshoot Z: 20mm (Adjust depending on box height variation)

- Zero sensor before execution + wait until sensor reading is steady before zero sensor

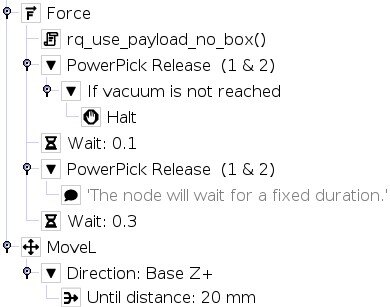

Node settings:

- Force: Frame, feature base, Z axis, 0N (The contact detection option of the palletizer node already apply this force), 150mm/s

- 1st vacuum release node: "wait for release to comple with release threshold" at 10%. Blowoff is desactivated.

- 2nd vacuum release node: "wait for fixed duration" of 0ms and "enable blowoff after release". Set a blowoff duration of 1000ms. This garanty that the cup does not stick to the surface and also clean cup filters.

NOTE : The blowoff maks sure the gripper does not stick to the surface and also help to remove dust form the cups.

- moveL: 200mm/s, 200mm/s2

NOTE : Starting 5.20.0 polyscope will be able to automatically set speed and acceleration to avoid protective stop. This feature is called optimove. Use optimove when it will be available.

Important : If you have a very tight pattern had XY approach distance in contact detection settings. This will cost about 0.5s but will prevent protective stop due to the collision with surrounding box.

How much time does it takes ?

- ~0.7s (0.2s for the zero and 0.5s to move to the surface) to make the contact detection (managed by the paletizier node)

- 0.1s to make cup atmospheric decompression

- 0.3s to make cup blow off decompression

- ~0.5s to move out

Maximum duration: ~1.6s

If you need to save time in the grip and release process. You can progressively remove part of the strategy until you get a good compromise between speed and stability.

- (-0.7s) Remove the "contact detection" option of the palletizer node.

Important : The draw back is that the robot will not accomodate box height variation. The robot is at risk to arrive too low and collision with the pallet or too height and drop the box at a random location.

- (-0.2s) Reduce wait time after blowoff.

Important : The draw back is that the robot may not have enough time to clear payload transition forces in the force node. If residual forces are too high the robot can trigger a protective stop.

- (0.5s) Remove the final vertical moveL or use faster speed and acceleration.

Important : The draw back is that the robot will start its trajectory with a high acceleration (This is how our palletizing trajectories works at the moment) and this can ease protective stop if residual forces are present.

Minimum duration: 0.2s