Context

This knowledge article intends to describe how to handle boxes overhang on a pallet with our Palletizing Solution.

Knowledge

Important: The Material Handling Copilot and the Online Simulator cannot work with boxes that overhang the pallet in any direction. One must work with a fictive pallet big enough to contain all the boxes and the real pallet is centered on the fictive pallet

Step 1 : determining the dimensions of the fictive pallet

Fictive Pallet Width = Total width of the boxes on the pallet

Fictive Pallet Depth = Total depth of the boxes on the pallet

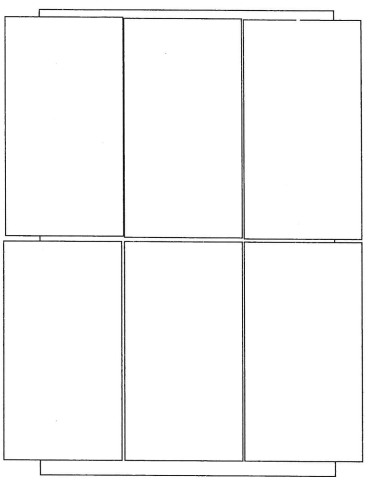

Example : The pallet pattern below requires a 1000x1200 fictive pallet.

Fictive pallet width = 3x Box Width + 2 x spacing

Fictive pallet width = 3x 320 + 2 x 20 = 1000 mm

And no overhang on the depth.

(EUR-Pallet : 800x1200, Boxes 550x320x160mm, up to 5 kg Payload)

Step 2 : Creating the pattern on the online simulator and the URCap

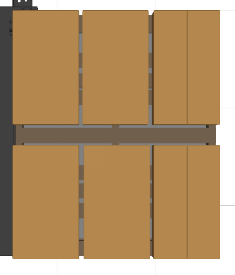

First one must create the pattern on a pallet the size of the fictive pallet.

Then one must places the boxes right where they would have been on the real pallet. The only difference is that this time it is possible as the fictive pallet is bigger and the boxes will not overlap the palletizer’s base.

In our previous example we would get the following pattern (same result of the URCap) :

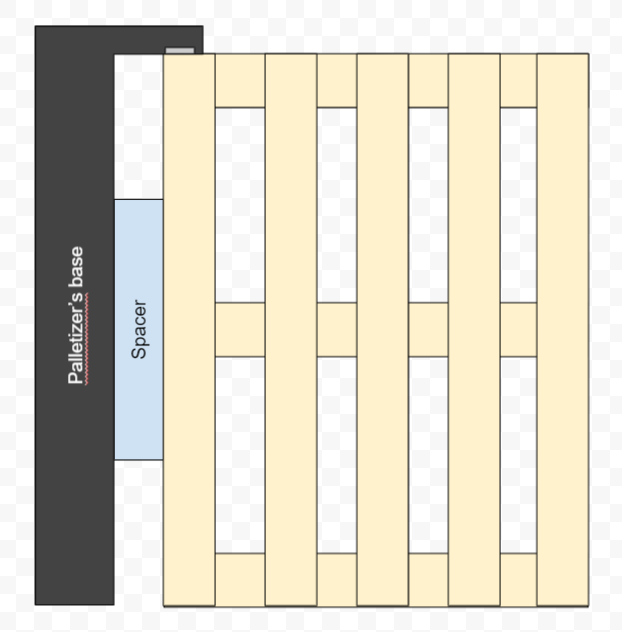

Step 3 : Placing the real pallet under the palletizer

One must place the real pallet so that the boxes will not overlap the palletizer’s base.

One easy solution is to use a spacer (see below).

Here the spacer is used to create a wider virtual pallet.

If one were to want a deeper virtual pallet, a spacer could be added on the top of the base as well.

The width of the spacer is equal to the overhang of the boxes on that side of the pallet.

In our previous example it would be 100mm wide, which is also (Fictive Pallet Width - Real Pallet Width)/2.

Step 4 : Handling the pallet sensors’ signals

When using a spacer, the corresponding mechanical pallet sensor is made non functional with the AX10 and PE10. However, the optical pallet sensors of the PE20 and AX20/AX30 models can work with the pallets a few centimeters away from the palletizer base.

In order for the software to keep working, one can duplicate the signal of the second (mechanical) sensor, or simply fake its signal by wiring a digital output to the previously attached to the sensor digital input.

Note: If working with multiple patterns and different overhangs, Fictive pallet dimensions are the following : Width = Max of fictive widths; Depth = Max of fictive depths.