How to Use the Grip Check Feature

Ensure objects are correctly picked before continuing the program

The Grip Check feature lets your robot confirm whether an object is properly grasped. This helps avoid errors in downstream tasks such as palletizing, assembly, or inspection.

Key Concepts:

Object Detection

-

The way this information is obtained depends on the brand and model of the gripper.

-

Some models (e.g., Airpick) include a URCap with ready-to-use detection.

-

Others (e.g., PowerPick) require using a robot input signal.

Variable(s)

-

A variable is an entity that can hold different values depending on program conditions or sensor feedback.

“If” Condition

-

A basic programming logic element that lets the system behave differently depending on whether conditions are met.

Grip Check before releasing on the pallet:

The goal is to verify the presence of a box just before releasing it on the pallet.

-

If a box is detected → release it on the pallet and continue.

-

If no box is detected → return to the conveyor and retry the pick.

-If there is a box:

- Release the box on the pallet

-Keep going

-Else:

-Go back to the conveyor

-Try again

How It Works in the Palletizing Solution

-

Box Detection

-

Most grippers provide object detection signals.

-

This signal is used to trigger the

ifcondition.

-

-

Retry Action

-

The Robotiq Palletizing Solution already includes a retry routine.

-

When no box is detected, set the hidden variable

rq_has_box = False. -

This prevents the box count from increasing and prompts the robot to retry the same pick.

-

Place this condition in the Release section of the program, since we want to confirm that the box made it from the conveyor all the way to the pallet.

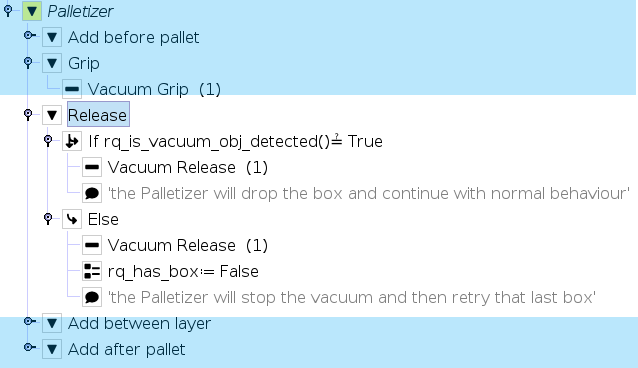

Object detection with Airpick

Airpick has a complete URCap with an embeded object detection feature. If an object is present, a variable called ''rq_is_vacuum_obj_detected()'' is set to ''true''. The condition initiating the ''if'' can be based on the value of this variable.

Here is an example of code:

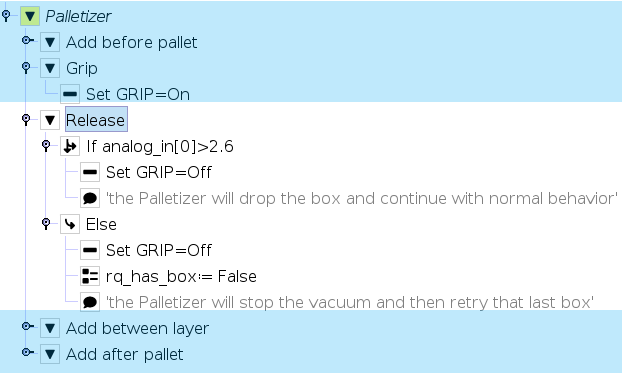

Object detection with Powerpick

PowerPick can either be used with basic I/O or the vacuum grippers URcap.

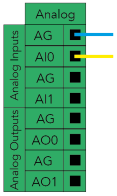

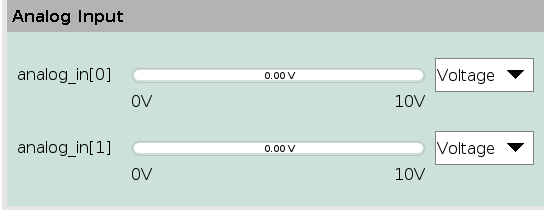

I/O method

One has to use the Analog Input (AI) of the vacuum level to determine if there is a box being gripped. As per the user manual, the vacuum sensor should be connected to Analog Input 0 (AI0) in the Universal Robot controller.

Step 1: Turn on and note the vacuum level without a box at the gripper (2.4V in this example).

Step 2: Turn on and note the vacuum level with a box at the gripper (2.8V in this example).

In this case, the condition for the ''if'' node should be the value of AI0 being halfway between the two values.

Condition Value = (Vwithoutbox + Vwithbox) / 2

Condition Value = (2.4V + 2.8V) / 2 = 2.6V

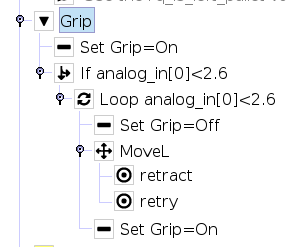

Here is an example of code:

Grip Check at Grip Position (I/O Method)

Another good practice is to verify the presence of a box immediately after activating the vacuum gripper at the conveyor.

-

If no box is detected, the robot stops, pulls back, returns to the grip position, and tries again.

-

This can be programmed as a loop until the correct vacuum level is detected.

-

Once the vacuum level is correct on the first attempt, the robot continues its normal cycle and places the box on the pallet.

URcap method

The "PowerPick Grip" node can also be used to implement a "grip check" feature.

Here is a description of the features of this node :

Note : Additional logic can be used trigger a retry routine. (The "Force" node is used to compress the suction cups on the box more than on the first attempt.)