Dual Input/conveyor Palletizing

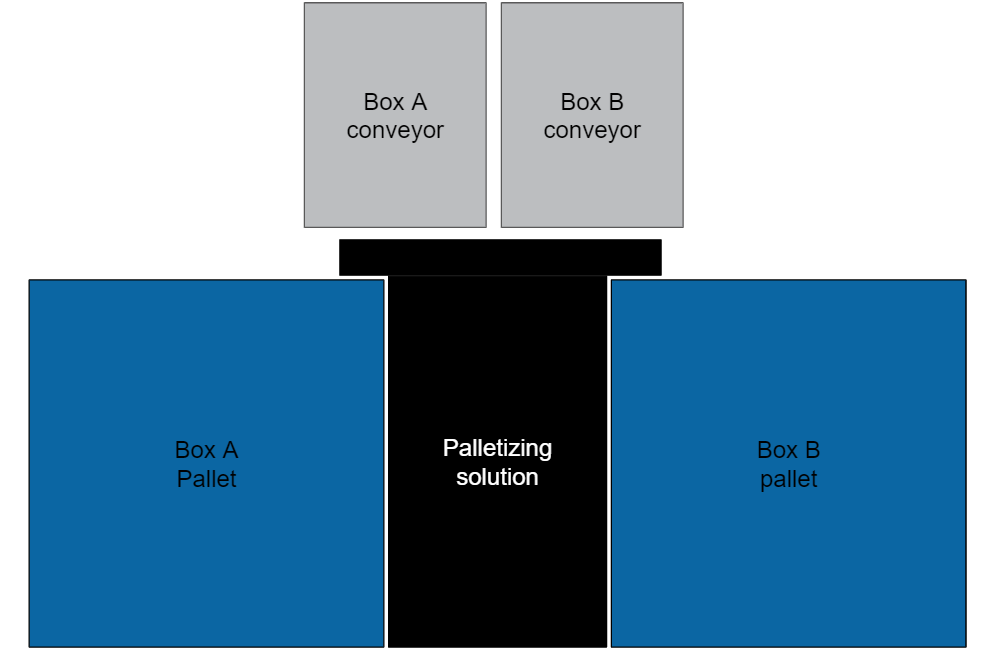

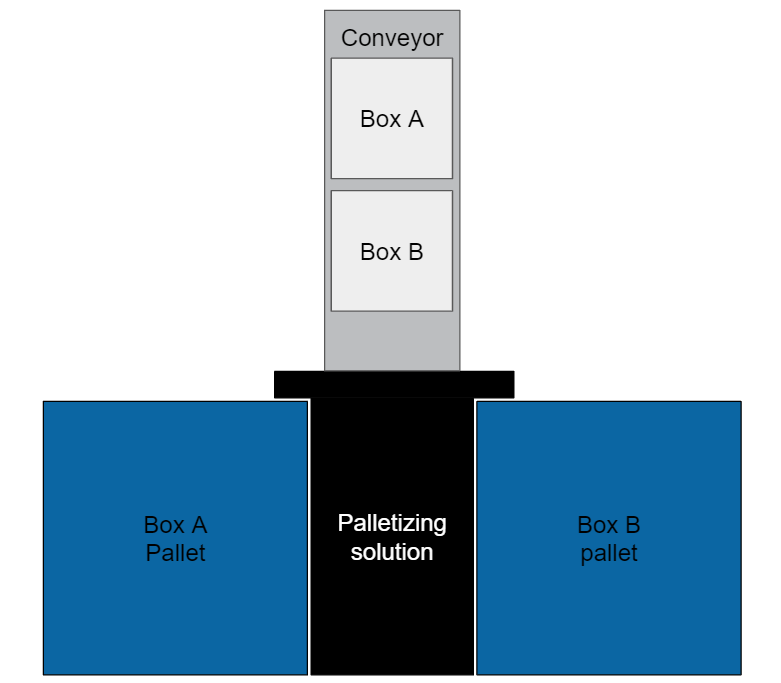

Context This application note presents a methodology for palletizing 2 types of boxes with the same Robotiq palletizing solution. Product A is on the left, and product B is on the right.

1. A and B boxes are delivered on separate conveyors.

The left conveyor handles boxes A for the left pallet, and the right conveyor handles boxes B for the right pallet.

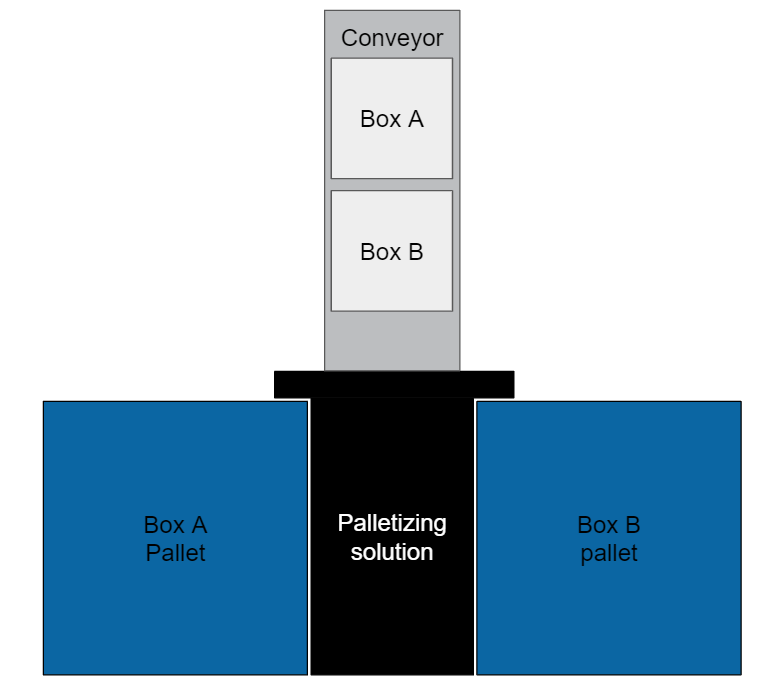

2. A and B boxes are delivered on the same conveyor.

In some cases, both types of boxes may be delivered on the same conveyor. When this happens, the system responsible for delivering the boxes must be capable of indicating to the palletizing solution which type of box is being delivered. This can be achieved using IO inputs, Modbus TCP, or other communication methods.

How to program

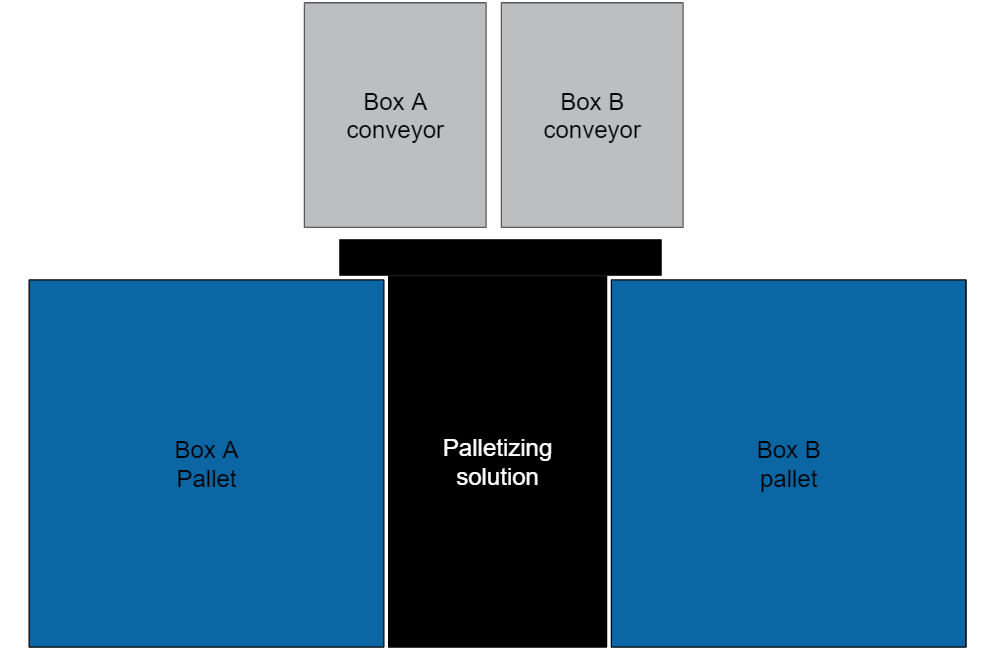

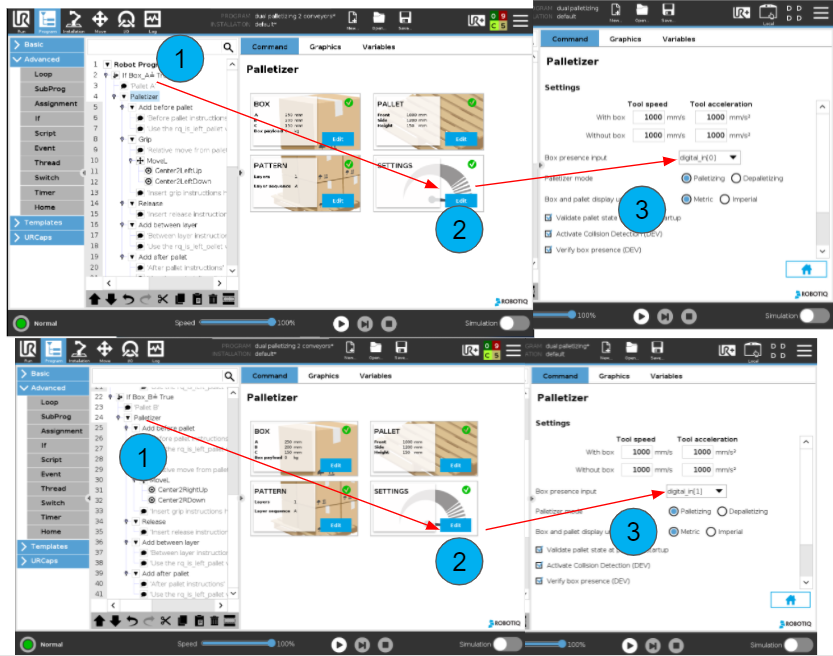

Case 1 : Using Two Boxes on Separate Conveyors

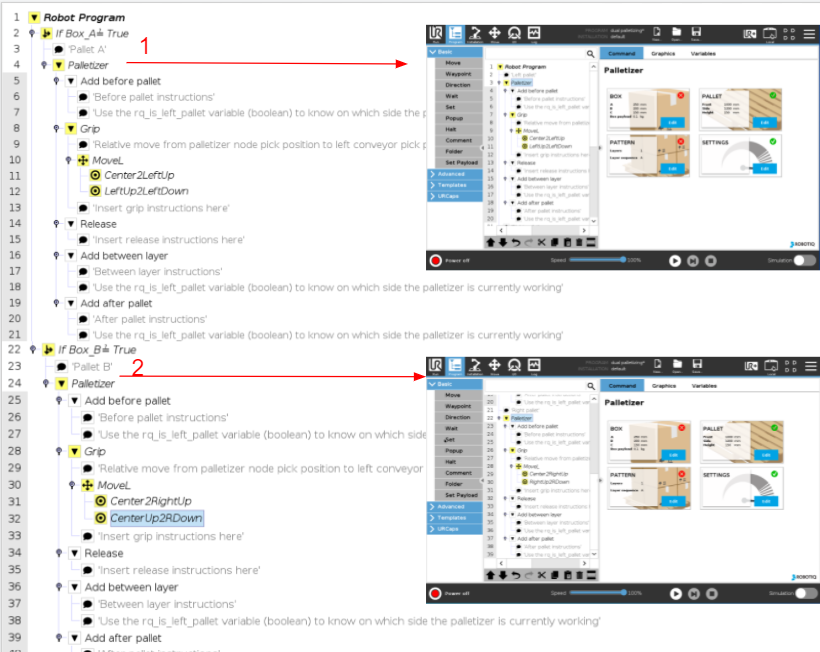

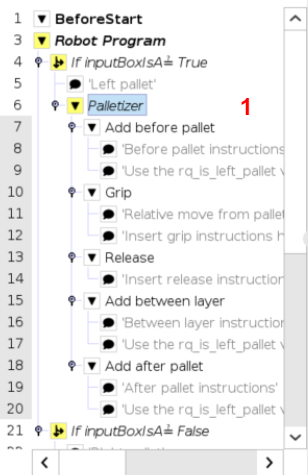

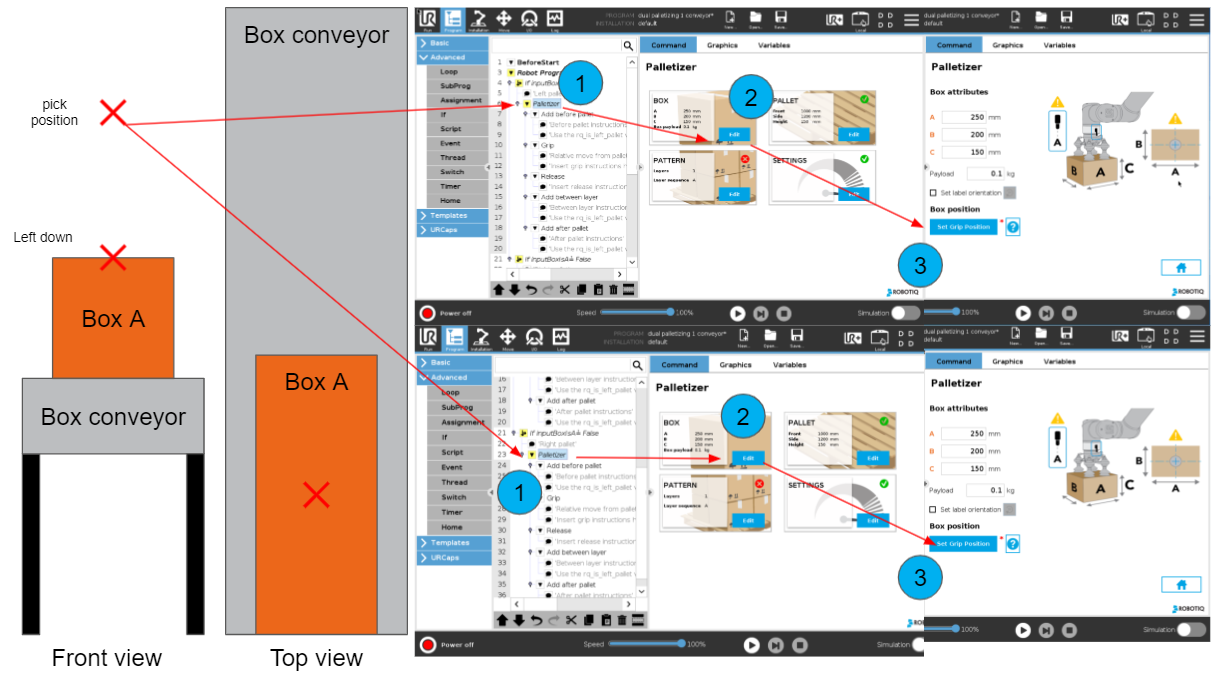

Here below is an example of a program to palletize using 2 conveyors. One for the left pallet and one for the right pallet.

It is composed of 2 Palletizer nodes. One node for the left pallet and one node for the right pallet.

It is preferable to insert each Palletizer node inside an '' If '' condition so the program does not wait for a box to appear. For example, it will just skip node 2 until ''Box_B'' is detected (''True'') and execute node 1 once again (if a box is on the other conveyor). In this case, ''Box_A'' and ''Box_B'' are the status of each box sensor.

Because boxes' presence have to be detected on the two conveyors, one box sensor has to be placed on each conveyor.

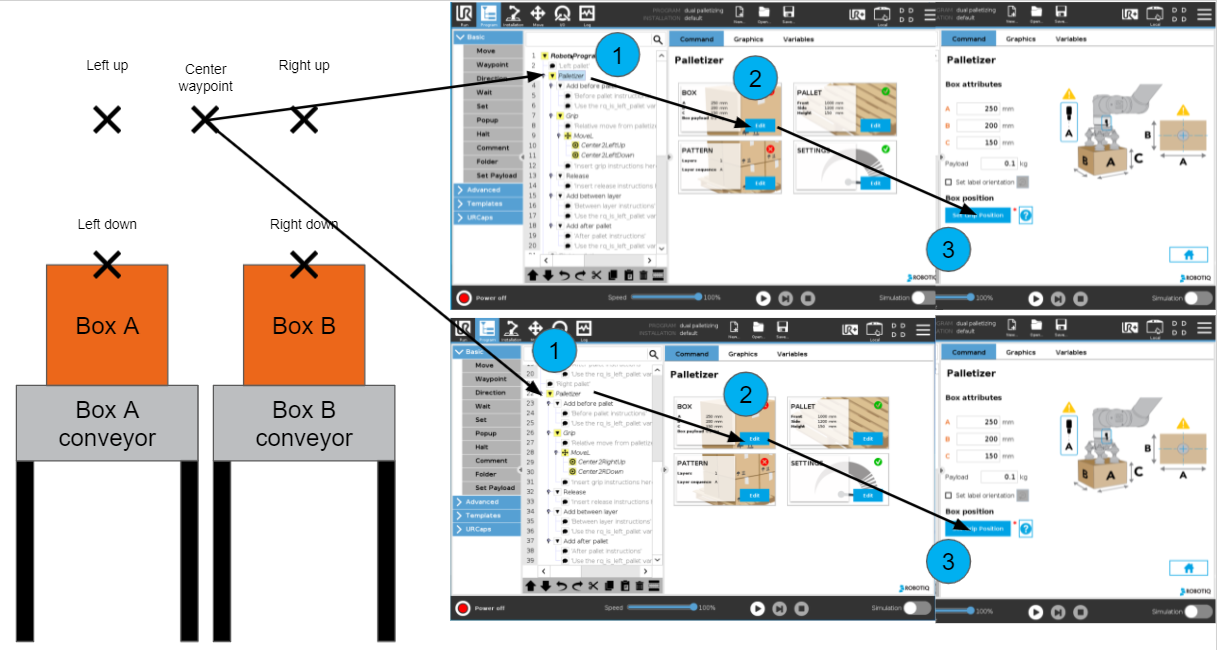

The Grip Position of those 2 Palletizer nodes is the same and is placed between the 2 conveyors above the highest box surface.

In the Grip folder of each Palletizer node, relative moves must be added to transit from the grip position registered in the palletizer nodes to the left/right pick position.

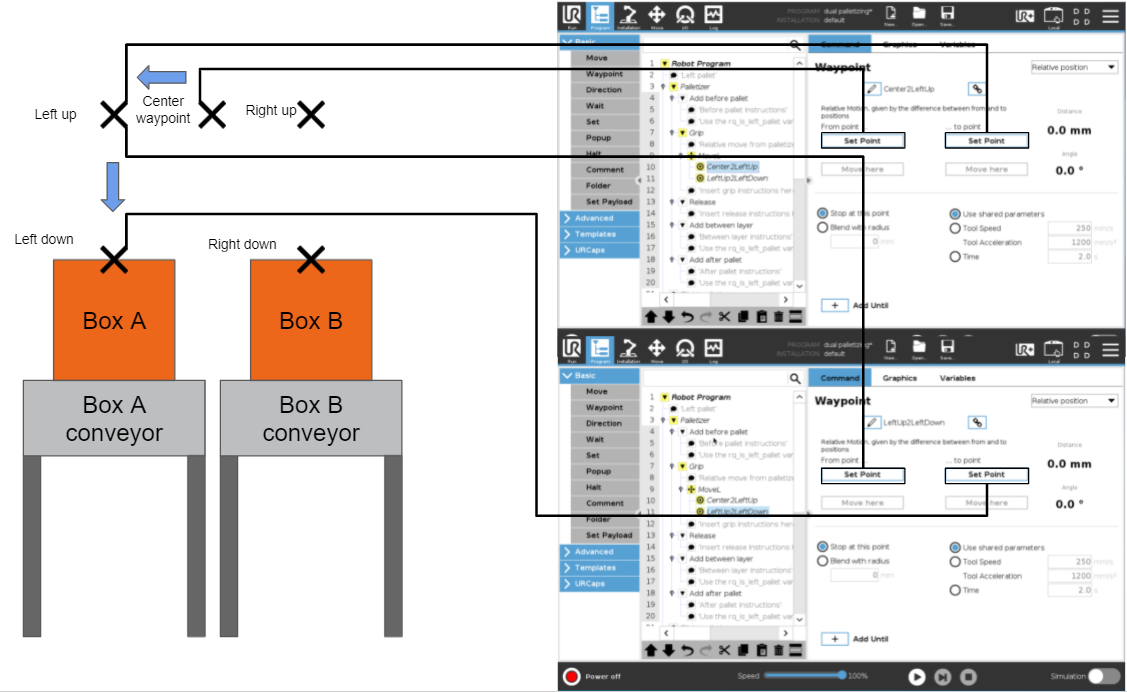

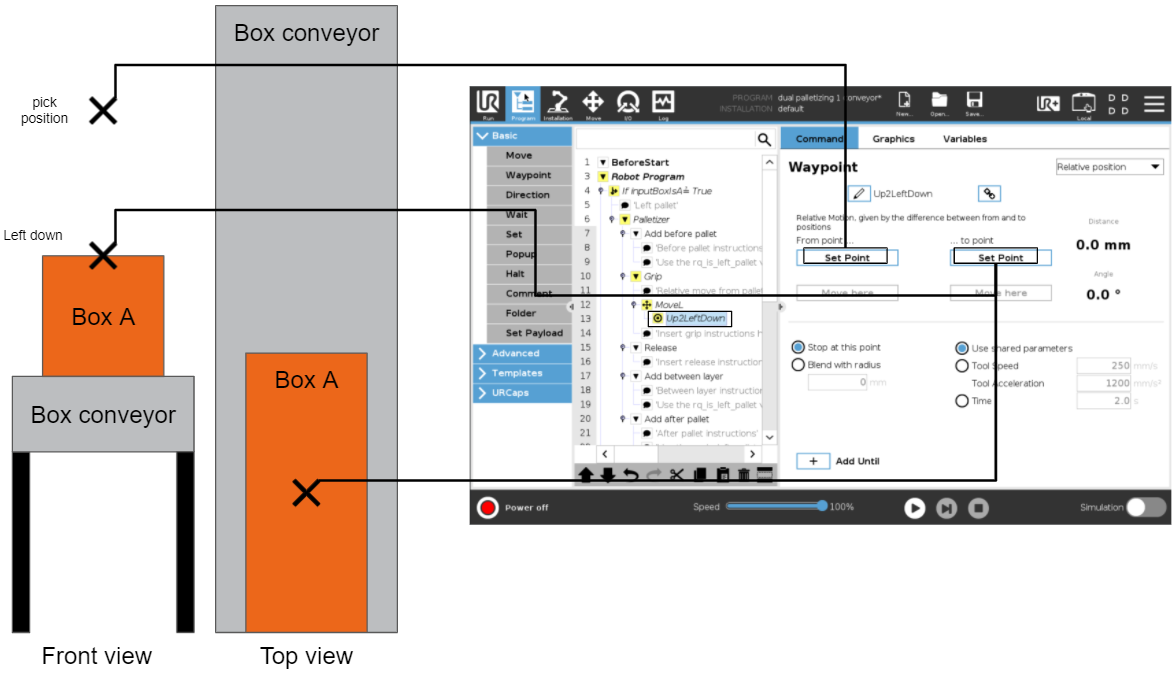

Here is how are set waypoints of the relative moveL, to go from the Grip Position of the Palletizer node to the left pick position.

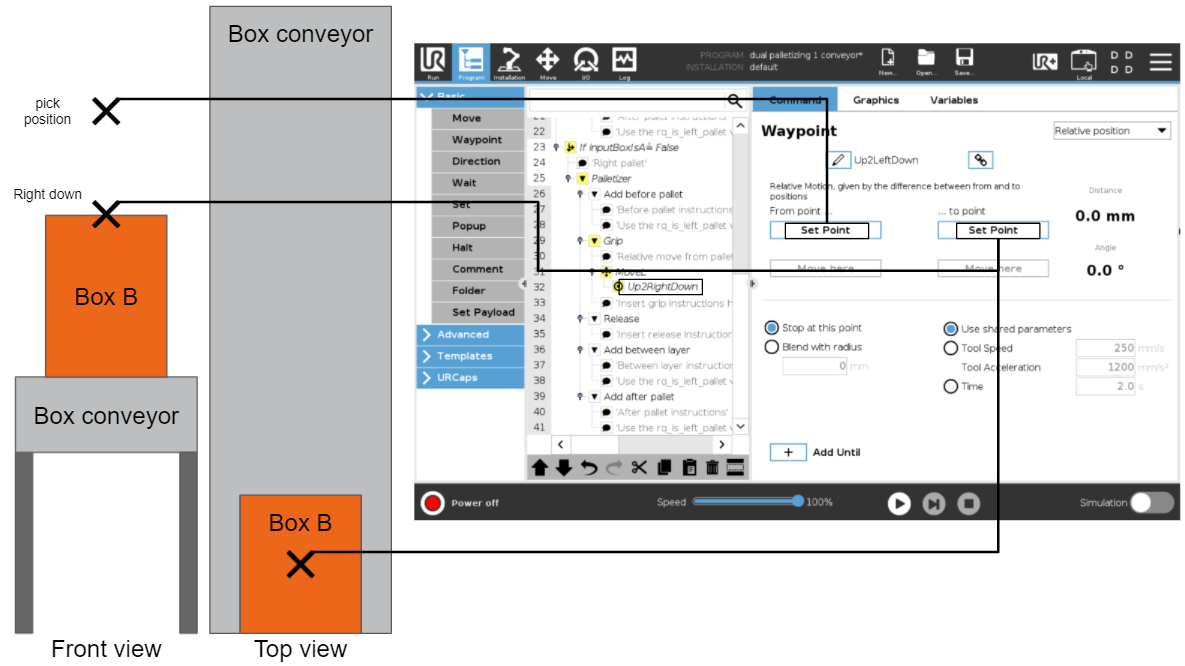

Below is the same process but for the right conveyor.

With such a program structure the system should be able to process the 2 conveyors input.

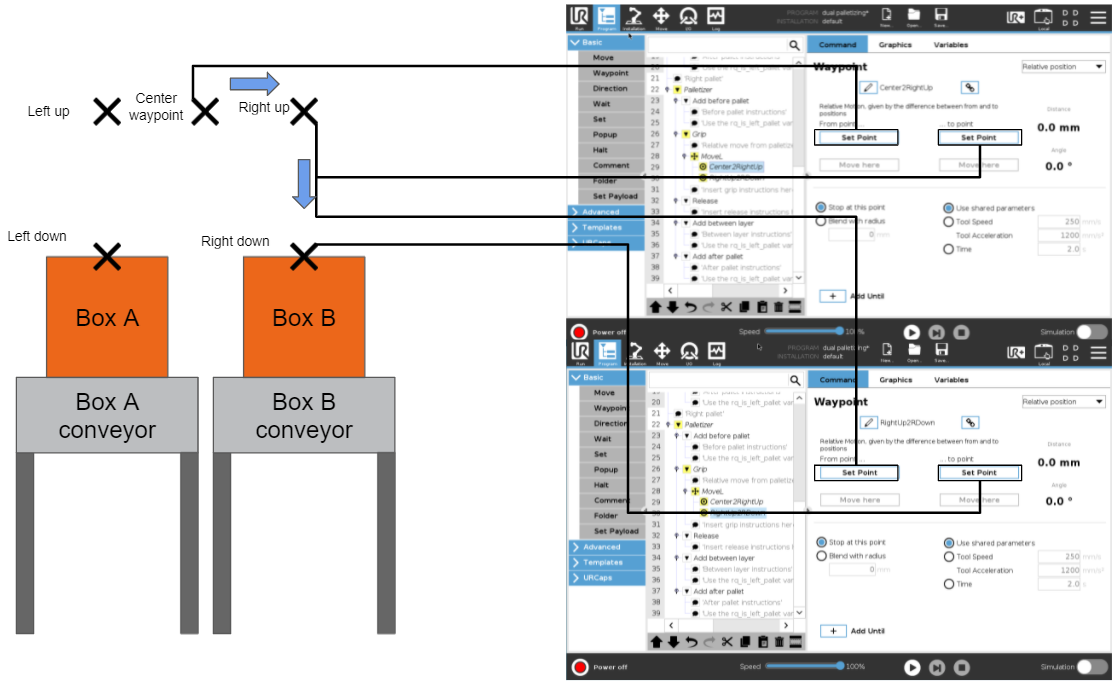

Case 2 : Two Boxes on the Same Conveyor

info : The system which delivers the box has to communicate to the palletizing solution which type of box is delivered. This can be done using IO inputs, modbus TCP or other communication methods.

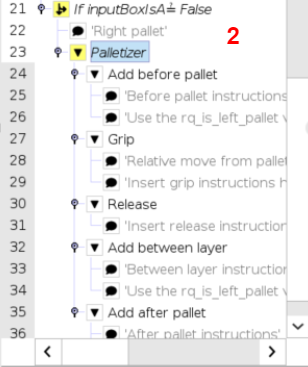

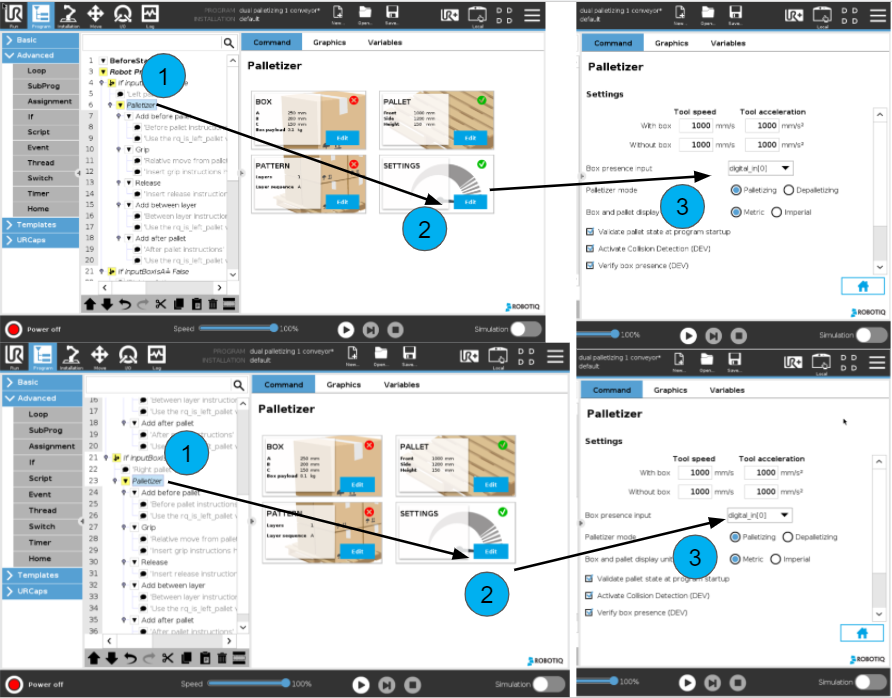

Here is an example of program structure to palletize with one conveyor delivering 2 types of boxes.

It is composed of 2 Palletizer nodes. One node is used for the left pallet and the other for the right pallet. Each node is placed under a separate ''If'' condition. The left node is executed only if the input box is a box A. The right node is executed only if the input box is a box B.

Both nodes use the same box sensor.

The Grip Position of those 2 Palletizer nodes is the same and is placed above the surface of the bigger box.

As boxes may have different sizes, it is necessary to add a relative move before the grip action of each palletizer node.

Here below is the relative move in case of box A (left side).

Here below is the relative move in case of box B (right side).

With such program structure the system should be able to process 2 types of boxes on the same conveyor.