How to Handle Box Overhang Using a Fictive Pallet

Use fictive dimensions and spacers to ensure compatibility with the simulator and Copilot when boxes exceed real pallet size.

Context

The Robotiq Copilot and Online Simulator require that all boxes fit entirely within the pallet boundaries. If your pattern causes boxes to overhang the edges, you must define a fictive pallet — a larger virtual area that fits all boxes — and align the real pallet accordingly using spacers.

Step 1 : determining the dimensions of the fictive pallet

Fictive Pallet Width = Total width of the boxes on the pallet

Fictive Pallet Depth = Total depth of the boxes on the pallet

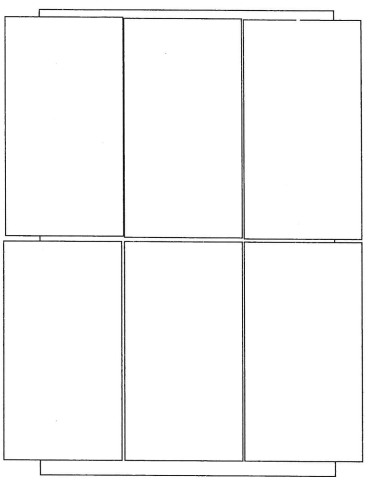

Example : The pallet pattern below requires a 1000x1200 fictive pallet.

Fictive pallet width = 3x Box Width + 2 x spacing

Fictive pallet width = 3x 320 + 2 x 20 = 1000 mm

And no overhang on the depth.

(EUR-Pallet : 800x1200, Boxes 550x320x160mm, up to 5 kg Payload)

Step 2 : Creating the pattern on the online simulator and the URCap

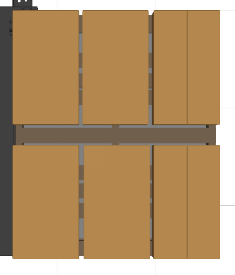

First one must create the pattern on a pallet the size of the fictive pallet.

Then one must places the boxes right where they would have been on the real pallet. The only difference is that this time it is possible as the fictive pallet is bigger and the boxes will not overlap the palletizer’s base.

In our previous example we would get the following pattern (same result of the URCap) :

Step 3 : Placing the real pallet under the palletizer

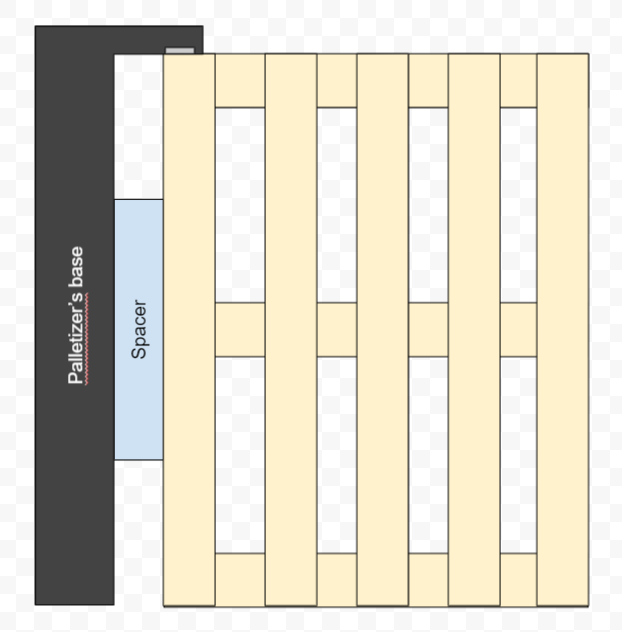

One must place the real pallet so that the boxes will not overlap the palletizer’s base.

One easy solution is to use a spacer (see below).

Here the spacer is used to create a wider virtual pallet.

If one were to want a deeper virtual pallet, a spacer could be added on the top of the base as well.

The width of the spacer is equal to the overhang of the boxes on that side of the pallet.

In our previous example it would be 100mm wide, which is also (Fictive Pallet Width - Real Pallet Width)/2.

Step 4 : Handling the pallet sensors’ signals

When using spacers:

-

AX10 and PE10: mechanical pallet sensors may become misaligned or disabled.

-

PE20, AX20, AX30: optical sensors can still detect pallets even if offset.

Solutions:

-

Either duplicate the signal from the working sensor.

-

Or simulate the signal by wiring a digital output to the input port previously connected to the disabled sensor.

Note on Multiple Patterns

If using different patterns with varying overhangs:

-

Fictive pallet dimensions =

Max Width across all patterns

Max Depth across all patterns

Conclusion

When boxes extend past the real pallet edge, a fictive pallet layout ensures safe programming and simulation. Spacers and sensor adjustments allow physical alignment without disrupting the palletizing flow.