First Amazon Picking Challenge

Posted on May 11, 2015 11:37 AM. 5 min read time

We are always really excited by robotic contest. If you have ever followed us for any period of time, you probably know that we have been involved with the teams who are participating in the DARPA Robotics Challenge. We also have our own internal robotic competitions to increase our common knowledge and to share this knowledge with our business partners. Now there is a new kid on the block: the Amazon Picking Challenge. The competition will be held in Seattle, WA during ICRA 2015. So why do Amazon and robots go together?

To make a long story short, Amazon is shipping millions of different items worldwide and is able to do so at a very fast pace. However, to be able to optimize their process, using robots in their warehouses seems to be the best way.

Amazon is already using Kiva robots (they actually own the company) to move their shelves around their warehouse. By doing so, they reduce the time spent searching and traveling that workers use to do. Now the worker is located at a strategic place and the shelves are coming to him. He then picks up the items without having to walk. Now they would like to pick up the object by using a robot and reduce the time spent searching the shelves for the item.

The issue is: They have more than a million types of items to pick from... which increases (slightly) the difficulty of automating such a task. So this is why they have asked various teams to compete in the Amazon Challenge to increase our common knowledge and build from this.

The problematic of automated picking in an unstructured environment is:

- Recognize the item: See what kind of object is present in the bin or on the shelf.

- Position recognition: Recognize the orientation of the part.

- Grasp planning: Orient the robot arm and tool to grasp the item correctly.

- Grasping strategies: Grasp the item with dexterity (try not to break it or try not to drop it).

- Motion planning: Considering the grasped object, what are the potential ways for the robot to release the object in the right spot.

- Task planning: Decide what the robot needs to do and how it should do it.

- Error detection: Feedback that tells if the object is well grasped or if the object has been dropped.

The Challenge

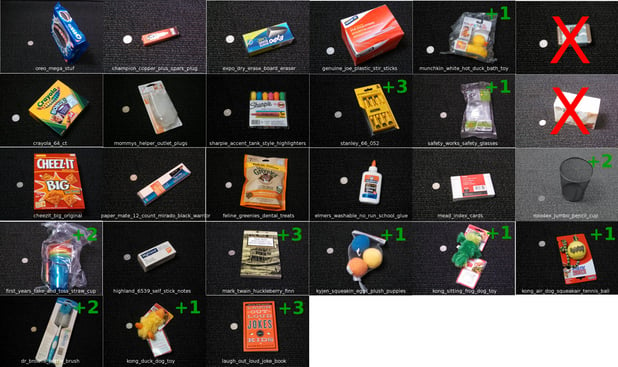

Now that you understand the complexity of the situation, you can see why Amazon is organizing a challenge to try and push the technology to achieve such a task. A total of 32 teams are registered for the contest. The way to evaluate the contest will be by the number of objects successfully transferred from one bin to another in an allotted amount of time. You can visualize the objects in the figure below.

One point is allowed for each object picked-and-placed in the right spot. Some objects are worth more points because of their complexity. The object will be placed in a bin on a shelf and to make life easier for the contenders, Amazon has limited the number of objects in each bin and the robot does not have to cover the entire shelf. This simplifies the problem compared to real life situations.

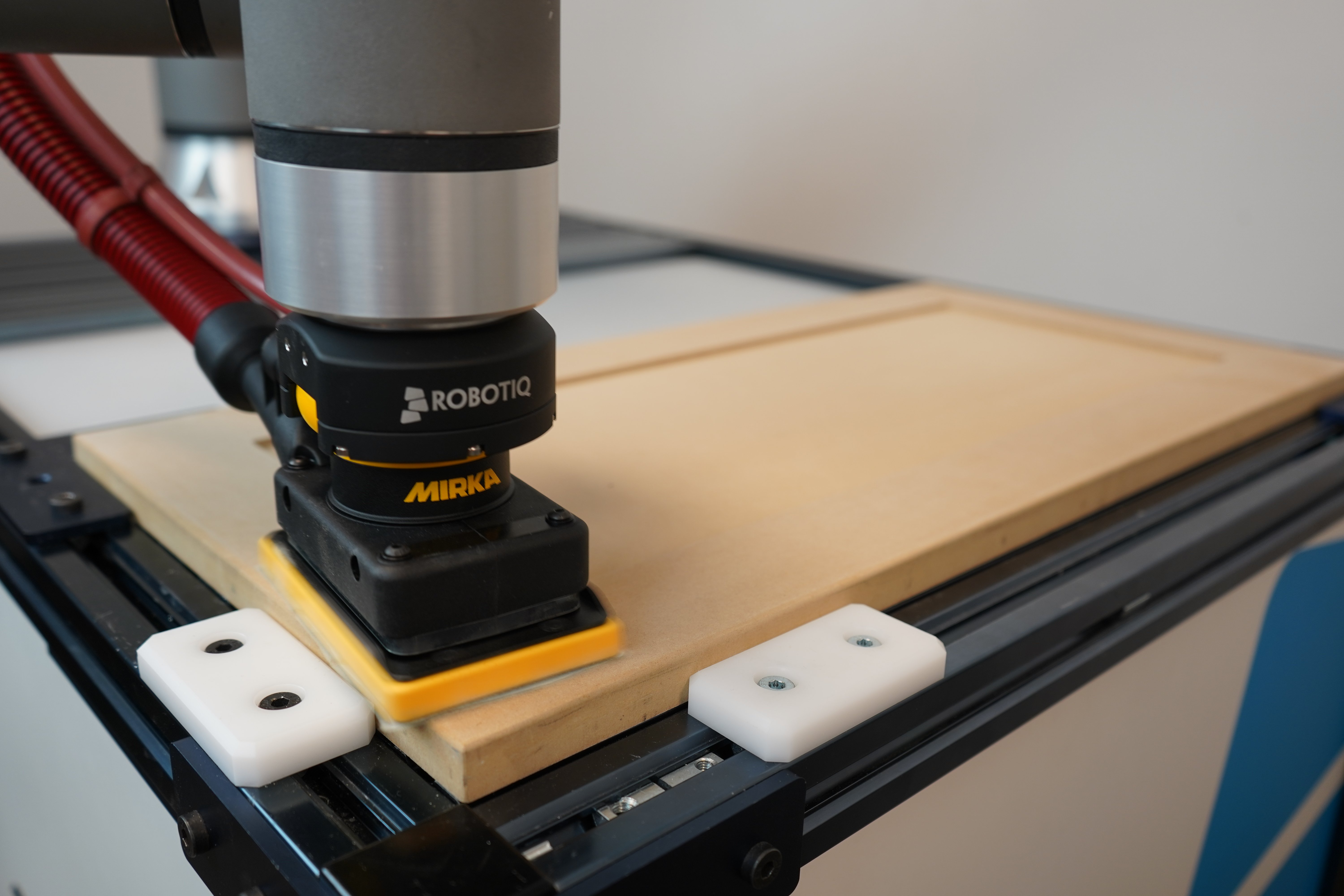

So the teams have to build a cell that can manage all the different difficulties related to the challenge. The cell will include devices such as a robot arm, a vision system and a robot end effector. Other devices can be used such as force torque sensors or tactile sensors to give feedback to the robot, for example if the item has been successfully grasped.

There are a bunch of bonuses and penalties that can be added to the final score. For example:

- Bonus: If there is more than one object in the picking bin.

- Penalty: If the object is dropped.

- Penalty: If the object is broken.

- Penalty: If the wrong object is picked.

The teams can use whatever robots they want, but the organization is providing robots on site. The robots provided are:

- Rethink Robotics: Baxter

- Clearpath: PR2

- Universal Robots: UR5

- Yaskawa Motoman: Various models

- Fanuc: Various models

The 26,000$ prize money is much lower than many other robotics contests such as DARPA's. Still, many teams are participating because it is a great, real-world challenge to which they can apply their research. I just can't wait to see the different solutions that will emerge from this contest. By brainstorming and putting a lot of motivated people together, you can advance the common knowledge in the field for this type of application and perhaps even find new ways to solve these kinds of problems. As with other robotic companies, we have a lot to learn and such a contest will give us the opportunity to understand what could be done better in the near future. Of special interest of course is the work of the teams who are using our grippers and force-torque sensors to address the challenge. We will keep you updated on the different results of the contest. In the meantime, you can take a look at the different research projects that have been done with our Adaptive Grippers.

Amazon

"At Amazon, we believe that innovation has the power to change the world. As we strive to become Earth's most customer-centric company, we constantly look for new ways to innovate on behalf of our different customers: individuals who shop our global websites, merchants who sell on our platform, developers who use our infrastructure to create their businesses, and creators of the books, music, films, games and other content we sell through our websites. We believe that our greatest contribution to the good of society comes directly from these core business activities." - Amazon Website

ICRA 2015

ICRA is the IEEE Robotics and Automation Society’s flagship conference and is a premier international forum for robotics researchers to present their work. ICRA 2015 is being held this year from May 26th to 31st in Seattle, WA.

Leave a comment