CNC MACHINE TENDING

The basic definition of tending is: the work of providing treatment for someone or something. In this particular case machine tending would be to load and/or unload a given machine with parts or material. Currently most of the applications involving machine tending are done by humans. Most machine shops are using their human workforce to load and unload machines and to restart the program once the finished part is out of the way. However, since qualified workers are becoming harder and harder to find, companies are introducing robots into their workshops to make up for the lack of employees.

What’s next?

- Explore the suggested content below

- Download the package

- Build your marketing & training activities

marketing package

Webinar

In this webinar, Mathieu Bélanger Barette, our Application Expert, explains the principles of the CNC Machine Tending with Collaborative robots. Learn how to sucess from experiences learned and challenge that will .

This presentation is also available without the voice over should you need it for your presentations or trainings. It is included in the package.

Record your own webinar! Download the presentation without the voice over and record yourself using OBS studio. Get the how-to guide in the marketing package.

Related videos

Automate CNC Machine Tending: Fusion OEM Case Study

Start CNC Machine Tending Faster With the New Robotiq Complete Kit

How to Design Custom Fingertips for Adaptive Grippers

APN Case Study

e-books

Robotic Machine Tending: How to improve CNC machine production

Machine Tending Playbook

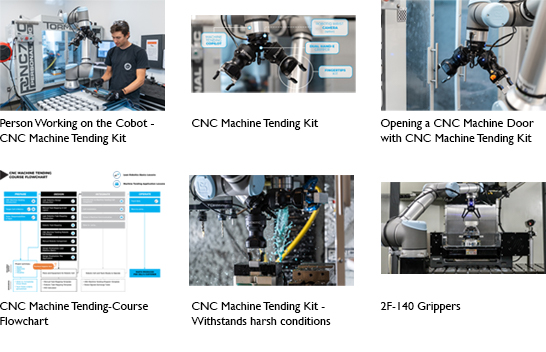

Pictures

MORE information

eLearning

CNC Machine Tending Application

CNC Machine Tending is one of the most popular applications for collaborative robots. Following the Lean Robotics methodology developed by Samuel Bouchard, CEO and co-founder of Robotiq, this course explains everything you need to know to build your own robotic machine tending cell. See below for a detailed flowchart. To reflect the Lean Robotics methodology, the course has been divided into 4 phases: Prepare, Design, Integrate and Operate. Under each section, you will find the valuable outputs as well as available resources.

Click here to access the CNC Machine Tending Application course

CNC Machine Tending Kit

In this lesson, learn how to install the CNC Machine Tending Kit and set the payload & TCP. You will also have tips on how to program a pick & place task with a dual gripper configuration.

Podcast

Our guest for this episode is CNC Machine Tending Application Expert Mathieu Bélanger-Barrette. We discuss how he and his colleagues worked on offering a CNC machine tending solution that meets the customer’s needs and helps them start production faster. What are the main blockers to a fast and efficient machine tending cobot cell deployment? Listen to find out!