Next Level for Human-Robot Collaboration – The CHARM Project

Posted on Aug 27, 2014 8:00 AM. 2 min read time

The next step in human-robot collaboration is to allow the human worker to control the robot without a teach pendant or controller. In fact, the ''Collaborative, Human-focused, Assistive Robotics for Manufacturing'' (CHARM) project is able to identify different human motions and react to these movements. The vision of the project is that future industrial robots will assist people in the workplace, support workers in a variety of tasks, improve manufacturing quality and processes, and increase productivity. CHARM is a multi-institutional project involving UBC (University of British-Columbia), Laval University and McGill University (Canada). All three universities bring different knowledge and ideas to the project.

The next step in human-robot collaboration is to allow the human worker to control the robot without a teach pendant or controller. In fact, the ''Collaborative, Human-focused, Assistive Robotics for Manufacturing'' (CHARM) project is able to identify different human motions and react to these movements. The vision of the project is that future industrial robots will assist people in the workplace, support workers in a variety of tasks, improve manufacturing quality and processes, and increase productivity. CHARM is a multi-institutional project involving UBC (University of British-Columbia), Laval University and McGill University (Canada). All three universities bring different knowledge and ideas to the project.

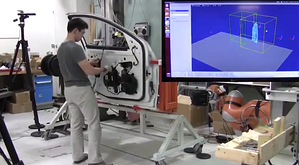

In the following video, the worker is entering into a workspace that has been predetermined by the robot program. The 3D camera is able to detect a certain number of pre-established gestures that are correlated into the collaborative robot response. For example, a gesture in the direction of the robot with the right hand means that the worker is requesting a part, so the collaborative robot, equipped with the 3-Finger Adaptive Robot Gripper, will respond by bringing various parts to the worker.

Certain gestures are used for a deficient part and others to signal to the collaborative robot to take corrective action. The 3D vision system is also able to recognize different working zones. This means that the robot can change working positions at the same station. The project is supported by GM Canada. This software/ hardware has been designed to enhance productivity in the automotive industry by developing ways to make the human-robot collaboration effortless.

Even if these projects are relatively advanced, we will still have to wait a couple of years before seeing them in action in real assembly lines. I am sure, however, that the robotic industry is waiting eagerly to see these applications introduced into their workshops and labs.

Leave a comment