Automation: Who Does What?

Posted on Feb 25, 2016 7:00 AM. 5 min read time

When you first start researching any business, you very likely might become a bit confused about who does what? Every person who wants to do business with you comes with the ‘I have the solution you need’ attitude. They might be right, but it depends on both what they have to offer and what exactly is your need. If you are looking to improve you production processes through automation, where do you start?

This is similar to a home improvement project, the perfect solution depends on:

- what you want to achieve,

- what you are able to do by yourself and

- how much time you are willing to spend on the project.

You could learn a lot of new things on your own, in order to do things by yourself and save money… but is this what you actually want? Determining where you are on the scale from “I can change these kitchen cabinets knobs myself” to “I might need to hire a contractor for a second-story addition” will help you get started on your project; be it home improvement or automation improvement. Sometimes, it might be worth investing a little money to hire the right expert and end up with a quality result.

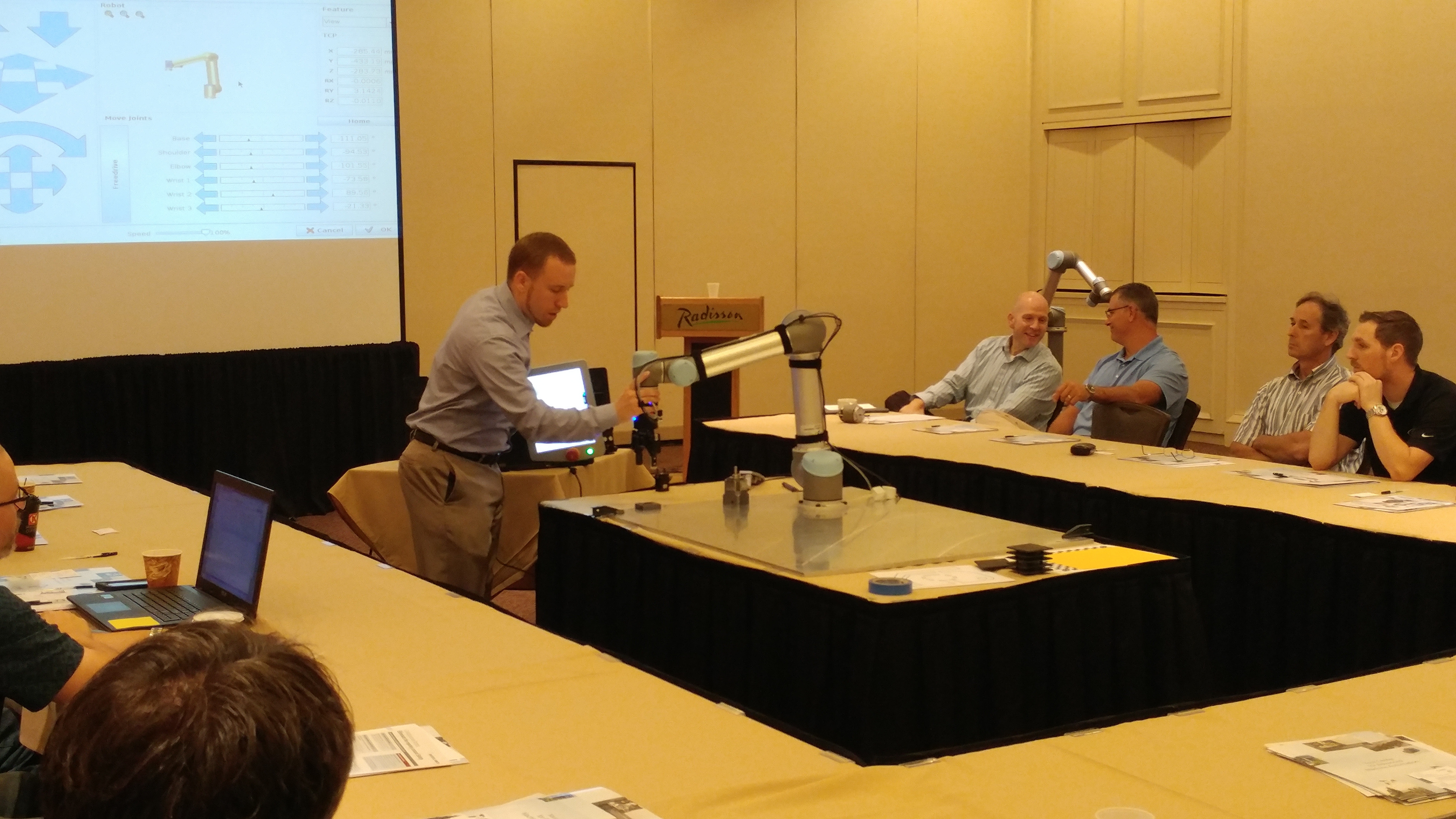

Automation integrator

I am no better than Wikipedia for definitions, so here we go:  “An automation integrator is a systems integrator—a company or individual—who makes different versions of automation hardware and software work together, generally combining several subsystems to work together as one large system.”

“An automation integrator is a systems integrator—a company or individual—who makes different versions of automation hardware and software work together, generally combining several subsystems to work together as one large system.”

Bottom line, this is your “contractor”. He has tried out various components of hardware / software, and different combinations of them in multiple contexts. He can sit down with you and discuss your potential application. He might have a solution off-the-shelf for you or he can design a complete system from scratch that will exactly fit your needs. On one hand, there are automation integrators that specialize in hardware, or a combination of hardware and software (e.g. camera and image processing software). On the other hand, some integrators are pure software specialists, e.g. MES (Manufacturing Execution System) integrators.

As for any other professionals that you hire, you should meet with a few of them before you actually decide on who you will be working with. There is more to a project than just the technical side of it. Analyze the quotes you get, but also trust your instincts. There are specialized or general integrators, but the same is true for clients… therefore, it’s good to know where you stand as a client. Are you a technology enthusiast that is willing to take some risk, because the technology has not been tried yet on your type of application? Or are you on the other side of the scale, i.e. you just want basic technology that has been proven to work on your type of application for the past 10 years or so?

You might even hire a third party to help you judge the quotes that you have been given. You could also research some of your competitors and learn about their experiences in automating, who have they been working with, etc.

Finally, when working with an integrator, keep in mind that the goal is to combine your strengths: you know the process, the integrator knows the potential automation possibilities. Respect each other’s strengths and weaknesses, and work together to end up with a satisfying result.

Component distributors

There are a wide range of component sellers out there – on the hardware side some sell direct i.e. what they actually produce, for example: robot / CNC suppliers; while others offer a wide selection of automation equipment (sensors, actuators, etc.). Robotiq’s Grippers are usually sold through the latter.

If you’ve never had a robot on your shop floor, and have very limited robotics knowledge, you might want to take advantage of the knowledge that the integrators can offer in setting up your first industrial robot. It is a good idea to be realistic about what you can do on your own and how much time and money you can spend on the development and learning process. That being said, robot suppliers could help you with identifying which processes in your plant would probably be the easiest to automate, and they probably can also refer you to a couple of integrators, so you should contact them for this valuable free information.

The case for CNC machines is a bit different, though. More and more CNC (Computer Numerical Control) machines are sold directly from the manufacturer to the end user. Also, modern CAM (Computer Aided Manufacturing) software has gotten much more sophisticated and user friendly, requiring a less demanding skill set to program tool paths. You might want to buy the CNC machine directly in this case, considering of course that you should get proper training from the CNC company that will sell it to you.

Some simpler components are pretty much ‘plug and play’ – smart cameras, for instance, can be plugged into a computer through an Ethernet cable and then configured through an intuitive interface. If there’s an inner geek hidden somewhere in your heart that craves to do some image processing, and you have a few thousand dollars to spare (let's say, about 3K), you could buy a smart camera and do your own tests, then take it from here to evaluate more robust solutions with an integrator.

The picture is pretty much the same on the software side: if you need an MES (Manufacturing Execution Systems), SCADA (Supervisory Control And Data Acquisition) or some similar acronym-software for your shop, you could either:

- buy directly from the company that developed the software;

- contact a distributor that offers software from various companies;

- or work with a software integrator that will take charge of the complete process from selection to implementation.

Colleges & Universities

Even though they usually do not sell equipment, universities and colleges can be great go-to places for discussing an automation issue, evaluating a potential solution or brainstorming solutions. Keep in mind that a university professor and yourself probably don’t share the same goals, e.g. advancing research VS being more efficient on your production line. However, some institutions will have very practical automation expertise and may have conducted many applied research projects. Therefore, they might have great solutions and ideas to offer. But, in order to know if you’re on the same page as the person you’re talking to, you could use the Technology Readiness Level (TRL) scale to help identify where the technology you’re talking about stands. This method estimates the Technology Readiness Assessment (TRA) of program concepts, so you can determine how realistic and applicable they are to your present situation.

Whatever you decide you shouldn’t be afraid to go out and get the information you need to help your company automate. There are many cases where installing a robot has helped a company to improve their production quality or increase their production output or both. If you are looking for some examples, check out our Resource Center. You might even find a company similar to your own there. Have a nice time shopping around!

Leave a comment