How Robots Help the Consumer Goods Industry Adapt

Can small companies keep up with the new, demanding consumer? Here's how robotics can help!

What's New in Robotics This Week - July 21

Manufacturing & Cobot Roundup; MIT's Cheetah3 makes stage debut; Spinning microbot motors (w/ bacteria); Robot Causes Outbreak...

How Will Manufacturing Robotics Change in 2017?

Robotics are the best thing to happen to manufacturing since the creation of the assembly line. In terms of production, cost,...

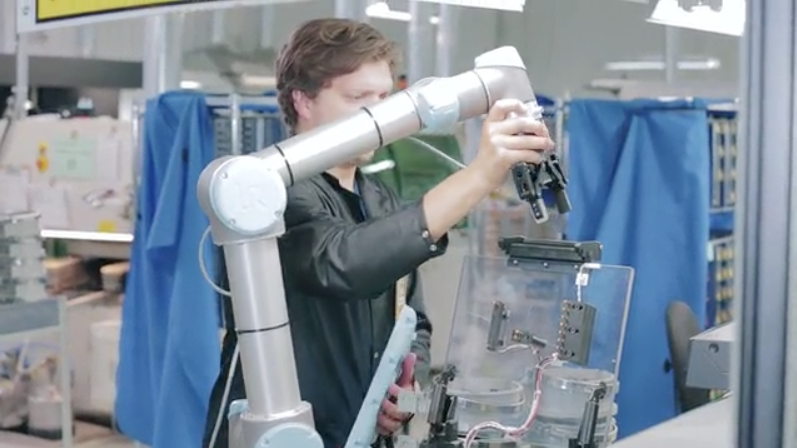

The 3 Most Common Tasks Delegated to Robots in Manufacturing

Robots have well and truly entered the field of manufacturing, but for many people, their exact jobs and tasks are still a...

How Difficult Is it to Implement Robotics Into a Manufacturing Plant?

Robots are the way of the future. Multiple industries have embraced the power and efficiency that automation offers for their...

3 Challenges Manufacturers Face When Implementing Robotics

As the world’s population continues to grow, and the demand for technology rises, manufacturers have larger orders to fill than...

Book Review: "Only Humans Need Apply – Winners and Losers in the Age of Smart Machines"

With the heavy media coverage and spotlight on manufacturing jobs and automation, it’s a good time to consider different...

Get the Team Onboard with In-House Robotics Expertise

You want to develop in-house robotics expertise. But, how do you convince the team? Here's how to get everyone onboard, from...

How Innovations in Robotics Are Eliminating Challenges in Manufacturing

Our world is one that’s focused on constant growth. Whether it’s growth in population, technology, or anything in between,...

Leave a comment