Robotiq to Release an Updated Interface for Universal Robots

Posted on Feb 10, 2015 11:25 AM. 3 min read time

Since the launch of the new version of the 2-Finger 85 Adaptive Gripper, the number of integrations on Universal Robots just keeps increasing. In our quest to simplify the use of our products we have developed an integrated, easy-to-use interface for testing and programming the 2-Finger 85 Gripper directly in the UR teach pendant.

The main reason why we developed this new interface is to simplify programming/debugging steps when integrating a 2-Finger 85 on a Universal Robots. Before you needed to program the robot with approximate values to test and debug the opening, force and speed features of the Gripper. Now with this graphical interface, it is a lot easier to test the parameters for a given situation. By cutting time and energy in your testing process, you can get back to production faster.

How Does it Work?

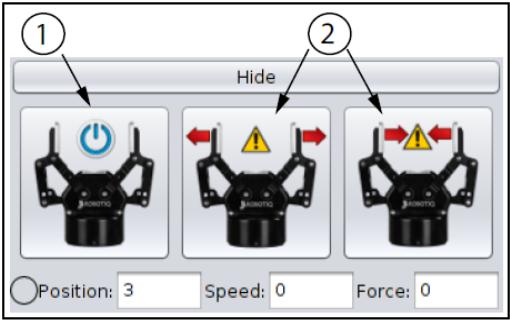

The interface is found in a single ''GRIPPER'' button that appears once your UR robot boots. When you click on the button, the following image appears.

This part of the new interface allows you to (#1) initialize your Robotiq Gripper and (#2) to structure your auto-release operations. Initializing your Gripper means the Gripper ''zeros'' itself and is ready to use.

The auto-release feature is basically for trouble shooting, for example, if you had a problem in a previous operation you can command your Gripper to completely open or completely close. So instead of programming operations in the pendant and waiting for the robot to execute them, you can directly release the part that is stocked in the Gripper. It's much easier and faster than ever before.

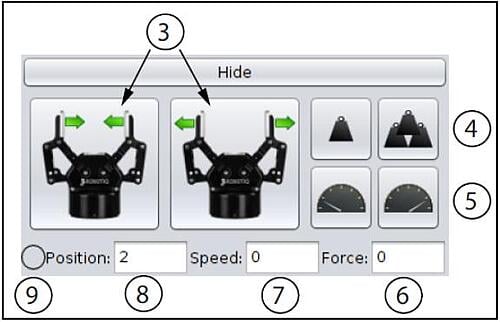

The second window of the interface allows you to monitor or test the Gripper. In fact, you can open or close the gripper (#3 below) using the tip of your finger. By simply pressing on the button, you can increase or reduce the opening. Note that the position digit marker goes from 0 to 255 and represent an opening from 0 to 85mm. Digits can vary depending on the initialization steps. To have further information always refer to the user guide.

Force parameters can be modifed by pushing on the button represented by the weight icon (#4). It can also be set with digits from 0 to 255. The lowest force value represent the lowest force. This setting can be reduced in case of fragile parts and can be increase in case of slippery or tough to grasp parts. Notice that the Robot Gripper can be set to a force from 60 to 200N.

The exact same principle applies for the speed setting button (#5). With speed marking digits going from 0 to 255, the finger speed can be set from 20 to 150 mm/s.

To monitor the different parameters of the Gripper, the 3 different digital indicators shows the value of the parameter in real time. Either it's for force (#6), speed (#7) or position (#8), these values will be updated immediately if you change any parameter and during the griping operation.

The last detail of the new interface is the object detection indicator (#9). Once the ''light'' turns yellow, the gripper is detecting an object between its fingers. This parameter is force related. This means, once the finger has reach a given force, the indicator shows the presence of a part.

With all these different parameters you should be able to parameterize and/or debug your 2-Finger 85 on your Universal Robots arm fairly easily. If you still haven't tried the 2-Finger 85 bundle for your UR, you should take a look at the following link to see the different advantages that can be obtained through using it.

Leave a comment