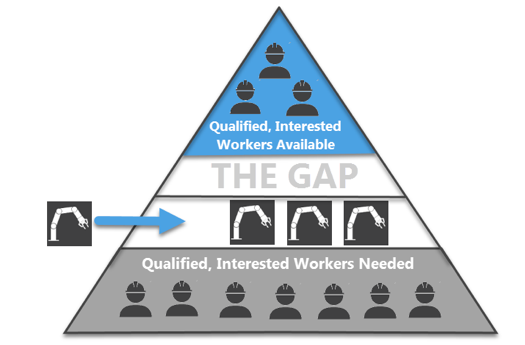

Decrease the Manufacturing Gap With Automation

Posted on Jul 03, 2017 7:00 AM. 2 min read time

Old manual assembly lines have already been largely replaced by automation; however, opportunities still exist to automate the tasks people don’t want to do or aren’t well suited for. Collaborative robots are an excellent example of new automation options that can help relieve some labor shortage problems.

It’s important to understand that you cannot simply wheel in a robot to replace a person (apart from in a few extremely specific instances). Implementation and integration just isn’t that simple. To integrate a collaborative robot, you have to start by identifying the task(s) most suited to automation with cobots.

Popular applications for collaborative robots include:

- pick and place

- machine tending

- dispensing

- packaging

To help relieve labor shortages, look for ways to integrate collaborative robots into production cells with tasks that people don’t want to do. By automating those tasks, you’ll free up those workers to take on other jobs that are harder to fill.

Jobs No One Wants

Here are some examples of unwanted jobs with corresponding cobot solutions.

Problem: Dull, repetitive movements that cause repetitive strain injuries in humans. Example solution: Use a cobot to place several screws on an assembly, and then have a human worker do the final screwing operation or verification.

Problem: Dirty jobs. Example solution: A cobot could dispense a toxic product such as glue or other chemicals.

Problem: Dangerous tasks. Example solution: A cobot could tend a machine that requires extra precautions, such as unloading a brake press.

Using a robot for applications that are potentially dangerous to a human worker removes or lessens risks for the workers, frees them from unpleasant jobs, and enables them to take on value-added jobs such as quality assurance instead.

Be Prepared for a New “Problem”

Old problem: Dull, dirty jobs no one wants to do.

New problem: Working with robots might require more technical skills. Fortunately, many collaborative robots are relatively easy for people to use, even if they’re inexperienced with robots. Cobots with touch-pads can be programmed simply and intuitively—no coding knowledge needed. Now an unpleasant job can become “cool,” thanks to a robotic helper!

Get the eBook exploring the skills gap, with a focus on solutions and strategies to close and fill the gap. We’ll explore the answers to questions you might have right now.

Leave a comment