Continental Automotive Pushes for Industry 4.0 With Robotiq and Universal Robots

Posted on Mar 13, 2017 7:00 AM. 2 min read time

When Continental Automotive Spain pushed Industry 4.0 in their factory, it saw the immediate advantage of easy integration, zero maintenance and higher productivity with the implementation of collaborative robots.

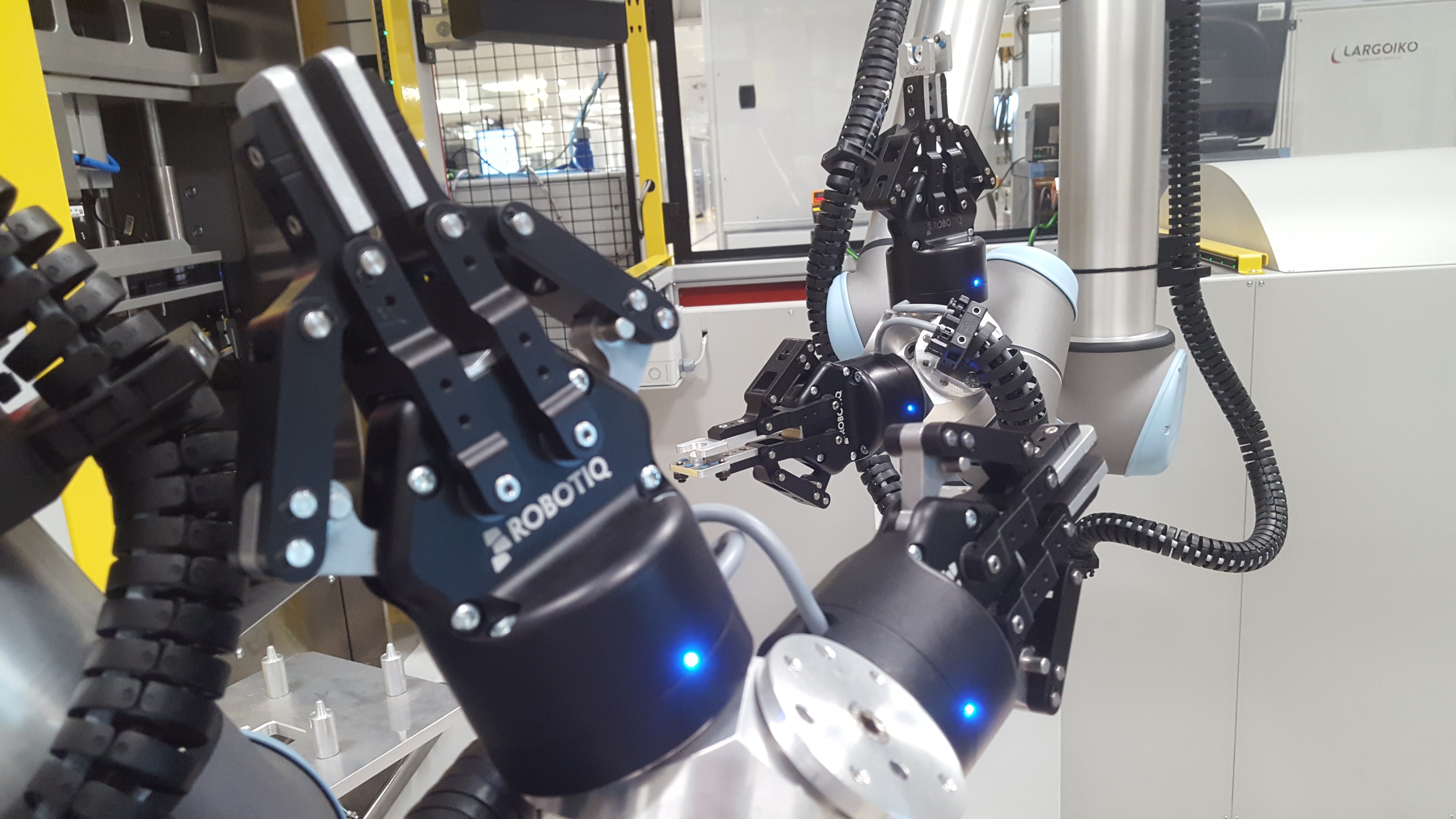

Continental Automotive Spain manufactures motor parts and accessories, such as dashboard displays for the automotive industry. Their factory counts around 500 employees and now a couple of robots. It was an important factor for Continental to follow innovation and implement Industry 4.0 in their factory. In fact, they implemented Universal Robots with Robotiq's 2-Finger Grippers in their production line.

Continental Recently Integrated Collaborative Robots to Their Production Line

Adding collaborative robots to the production line allows an easy integration since there is no need for much protection around the machines. There is also no need for many sensors around the equipment, which makes the machines efficient and cheap.

With the use of collaborative robots, Continental was able to reduce changeover time by 50%. Changeover time before collaborative robots was around 40 minutes; now with collaborative robots, it has gone down to 20 minutes.

Continental was fortunate to have the robots beforehand in their factory, which enabled them to conduct tests in a room with controlled situations to calculate cycle time and movements. The industrial engineering department was in charge of leading the introduction of these robots on the production line. None of them had previous experience in programming robots but with the help of Universal Robots and Robotiq's distributor, Vicosystems, the learning process required only a few weeks of training. The entire project took 6 months to complete, from idea to production.

One main benefit for using collaborative robots on this line includes the programming logic, which happens inside the robot. Also electronics, robot controllers and PLCs are integrated in the robot's central control box. This means that any modifications can simply be done by Continental as the programming of the robot is done in-house.

Of course, another great benefit is the fact that operators are now promoted to more value-added tasks around the factory. Instead of focusing on repetitive tasks, employees can now bring ideas and suggest ways to improve the production process. This is why the introduction of collaborative robots in manufacturing plants can stimulate innovation, which is exactly what this manufacturing leader pursued.

Leave a comment