Are Humans Outdated? What Robotics in Manufacturing Means for the Working Class

Posted on Feb 13, 2017 7:00 AM. 3 min read time

Robotics have come a long way in the last decade. From barely being able to stand or walk, now they are assembling smartphones and performing manufacturing tasks better than any person ever could. As a result, over 5.6 million jobs vanished between 2000 and 2010. A mere 13% of this was due to international trade, the rest was attributed to machines replacing human workers.

These kinds of statistics can certainly frighten people who are afraid of robots stealing their jobs, but is that really the case? What if this new surge of robotics actually has our best interests in mind? Today we’ll look at the rise of robotics in manufacturing, and what it means for the humans in the industry.

Leaving Humans in the Dust? The Reality of Robotics Manufacturing

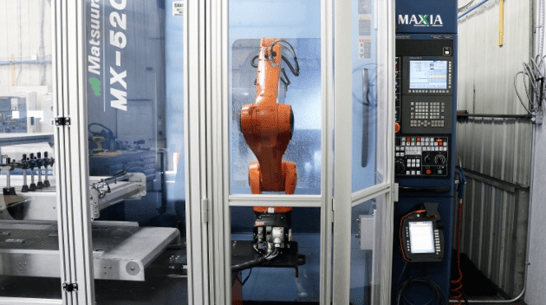

The simple fact of the matter is that today’s robotics technologies can perform menial and even precise tasks better than their human counterparts. They can do it faster, and they never complain or ask for more wages.

From a business standpoint, it’s the ideal solution. Productivity goes up and costs go down. This brings us to a two-way street where we can either fret about the loss of jobs apparent by the rise of robotics, or we can look at how this immediate downturn in jobs could in turn lead to a better future overall.

As it stands, we have a lot of major companies making huge pushes in the field of robotics. For example, Foxconn has improved its technology to the point where their robots can now assemble iPhones, resulting in 60,000 workers being replaced by, you guessed it, robots.

All of this leads to a mindset where we fear a future that totally removes humans from the picture. This thought process goes all the way back to Thomas Mortimer, an English writer and economist who described this exact fear in his 1772 paper entitled “Elements of Commerce.” In this paper his fear was brought about by the existence of automated sawmills.

Bringing jobs back to the U.S. is the focus of our current economic climate, and to this end, we need robotics to provide the productivity that companies want for their dollar. Yes, we will lose out on jobs, but let’s not embellish the loss here. These are menial jobs performed by people who would rather not do them in the first place. Instead of fear mongering, let’s take a look at a few ways this trend could be beneficial.

The Benefits of Robotic Manufacturing Trends

Beyond the simple act of eliminating menial work, growing trends in manufacturing are creating new industries and opportunities for better paid work. Companies like Amazon, for example, are hosting robotics competitions to see what engineers can come up with in terms of improved systems.

The need for robotics will in turn create an equal need for people to build and train them. This leads us to our second benefit: collaborative robotics. In a lot of cases, these robots that are placed into factories can be trained to work safely with humans and cooperatively accomplish tasks.

This would reduce the number of jobs, but it would increase the value of each person working with the company as they would be an integral part of a hybrid solution that combines both robotics and people.

We also shouldn't discount the types of jobs that robots are taking. These tend to be boring, repetitive jobs that manufacturers are constantly trying to fill with human workers. People want better jobs than that, and they will have them if the robots can take over the menial tasks.

Final Thoughts

Robotics in manufacturing are something to be embraced, not feared. While the immediate effect may seem negative, the long-term solutions that they pose offer a much brighter future for the industry as a whole.

What do you think about these issues? Do you see a silver lining in the manufacturing robotics debate? Let us know in the comments!

Leave a comment