4 Questions to Ask When Performing a Risk Assessment for Collaborative Robots

Posted on Jun 07, 2016 7:00 AM. 4 min read time

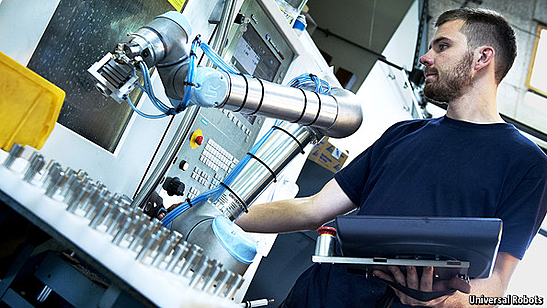

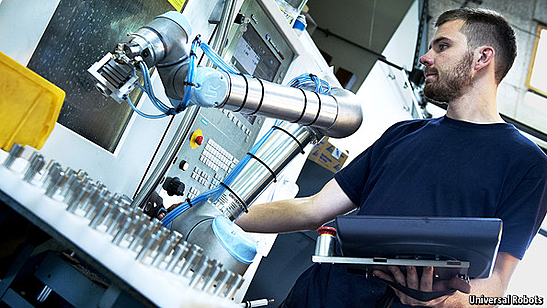

Industrial robotics has changed significantly with the advent of collaborative robots that are more aware of their surroundings, and amenable to the people around them. While our manufacturing counterparts were once literally caged off for fear that their unbridled movements would quite literally sweep us off our feet, we can now work alongside robots with very little risk. This revolution might seem to require fewer safety measures, but in reality you aren’t off the hook when it comes to risk assessment, even with the latest technology in collaborative robots.

What is a Collaborative Robot?

Different from its predecessor, the industrial robot, collaborative robots always consist of a robotic arm with an end effector, which

interacts with the environment around it. Industrial robots typically work in their own environments separated from any interaction with humans because they have no intelligence, but instead are the mere brawn behind many manufacturing facilities. With the unending stream of advancement in artificial intelligence and human robot interaction, the gap between human and robot workers is only growing smaller. This revolution is the result of a fundamental philosophical shift in engineering and design. Industrial robotic designs completely excluded human interaction as a variable, whereas new technologies are springing out of the idea that if a robot is capable of avoiding any harm to a person, why not allow contact? This newly evolved aspect of manufacturing is now accompanied by a new set of safety guidelines that give developers and end-users a better idea about the risk of employing collaborative robots.

Technical Specifications for Human-robot Interaction

Published in February, 2016, the ISO/TS 15066 Robots and Robotic Devices – Collaborative Robots, is a technical specification that offers

specific means for risk assessment in using collaborative robots in manufacturing settings. Before the publication of this document, suppliers and integrators had only general information about the safety requirements for collaborative robots. The ISO/TS 15066, however, gives specific and data-driven guidance for developers and users to both evaluate and control risk in their coworking environments. These new technical specifications regarding speed, force and pressure measurements will aid the industry in many ways, guiding developers and users, while also encouraging investors to take the field more seriously. That said, technical specifications generally indicate that the field in which they operate is in a transitional phase and therefore needs continuous improvement.

The New Risk Assessment

When robots existed in their own confined workspace, outside the human realm, risk assessment meant something completely different than it does today. Now that design takes for granted human contact, companies need to consider risk assessment as something that is not simply volume based or completely set in stone. Instead, risk assessment with collaborative robots ought to be thought of as sequence based, and a process that is evolving over time as the technologies and methodologies do. With collaborative robots being easily reprogrammable, there is a greater possibility for processes to evolve over time, and therefore the need for new risk assessments as well.

4 Questions to Ask in Risk Assessment

- How fast can this robot move?

The speed at which a robot can move may not be the optimal speed at which it should move to meet the appropriate work cycle times of the humans it is working alongside. Oftentimes collaborative robots will speed up and slow down throughout a cycle to ensure that it is in step with its human coworkers. If the robot is doing a certain operation away from the human worker you don't need to limit its speed. You can have different speed zones that will allow to speed up your process and still be safe within the presence of human workers. - How far is its reach?

This question will help you determine where the potential for its contact with humans lies and will then help you address further questions of speed and safety. Along certain trajectories and in specific places your robot may be able to work faster and with less risk than at other points in a cycle. - How dangerous is the process or sequence the robot is performing?

Is your robot carrying a sharp or extremely heavy object? Consider placement and speed if there is added risk because of the task your robot is performing and its proximity to humans. - How can I prevent collaborative robots from being a workplace hazard?

The ISO/TS 15066 offers guidance on implementing certain collaborative techniques, that are data driven technical specifications designed for collaborative robots. These specifications include a safety-rated monitored stop, hand guiding, speed and separation monitoring and power and force limiting. By reading and following these technical specifications your collaborative robots will be safe to work alongside humans.

If you are in need of help in performing a risk assessment for your collaborative robot, there are many experts to call who specialize in streamlining robotic processes, while performing industry approved risk assessments on all of your coworking robots. The collaborative robotics industry is constantly changing, and requires that risk be reconsidered at every iteration. By asking these four simple questions you will get a better idea of where your risk lies, and how to take the necessary precautions.

Leave a comment